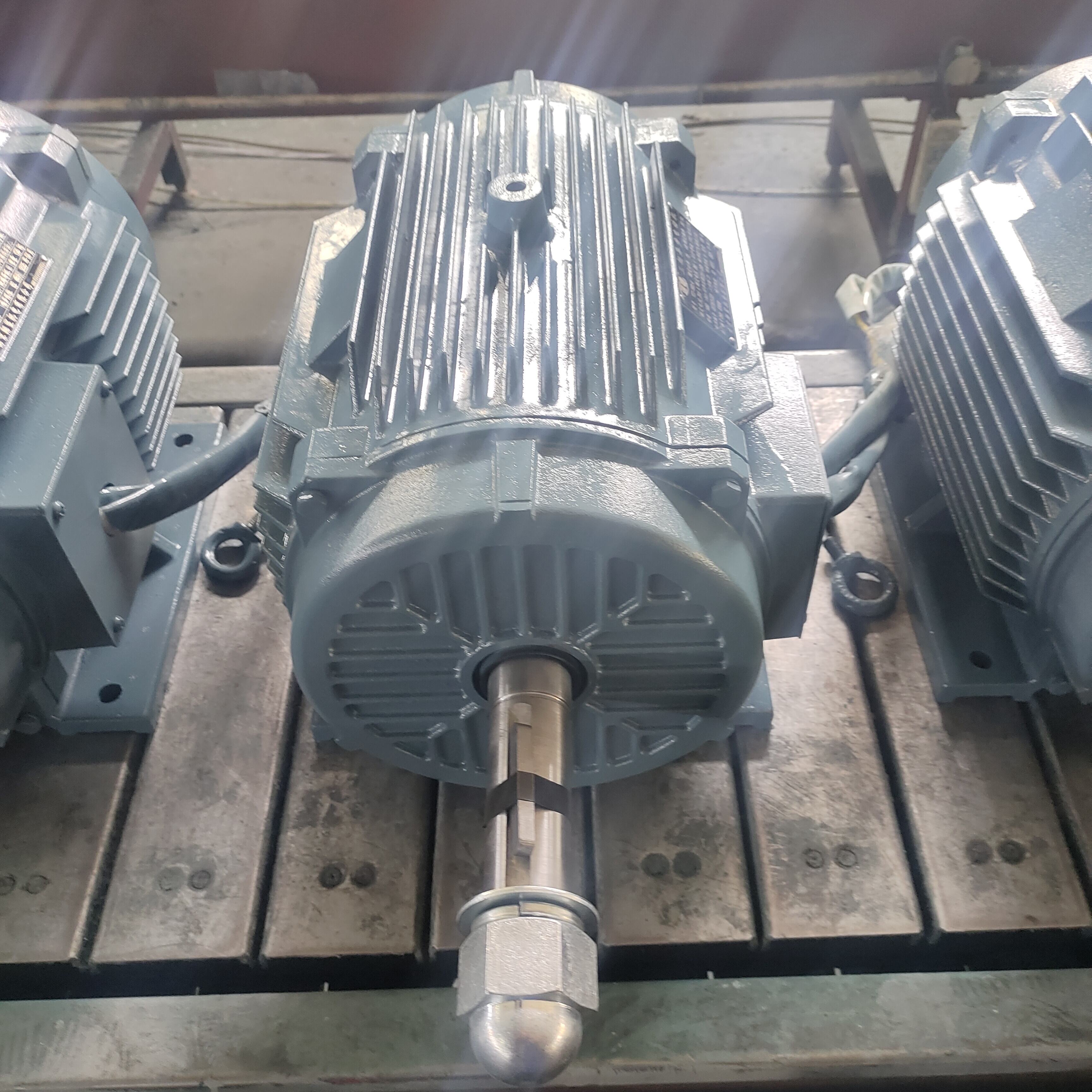

Versatile Performance Across Diverse Industrial Applications

The versatility of the low price asynchronous motor makes it an indispensable component across numerous industrial sectors, demonstrating adaptability that few other motor technologies can match. This versatility stems from the motor's ability to operate effectively across a wide range of power ratings, from fractional horsepower units suitable for small machinery to large industrial motors capable of handling substantial loads. Speed control options provide flexibility for applications requiring variable operating speeds, with simple and cost-effective control methods available including variable frequency drives, pole changing configurations, and voltage control systems. The motors excel in applications requiring constant speed operation, maintaining stable rotational velocity regardless of minor load variations, making them ideal for fans, pumps, and conveyor systems where consistent performance is critical. Starting characteristics accommodate various load types, from low-inertia applications requiring quick acceleration to high-inertia systems that need gradual speed buildup. The low price asynchronous motor demonstrates exceptional performance in continuous duty applications, maintaining consistent output over extended operating periods without degradation or performance loss. Intermittent duty capabilities allow these motors to handle applications with periodic operation cycles, automatically adapting to varying thermal and mechanical stress patterns. Environmental adaptability enables operation in diverse conditions, from clean manufacturing environments to harsh industrial settings with exposure to dust, moisture, temperature extremes, and chemical vapors. Different enclosure types and protection ratings ensure suitable options for indoor and outdoor installations, hazardous locations, and specialized industrial environments. Load matching capabilities allow proper motor selection for specific applications, with various torque characteristics available to match different mechanical load requirements. The motors integrate seamlessly with existing industrial control systems, accepting standard control signals and interfacing with programmable logic controllers, safety systems, and automated manufacturing equipment. Installation flexibility accommodates different mounting orientations, shaft configurations, and connection methods, enabling integration into space-constrained installations and specialized machinery designs. Power supply compatibility spans various voltage levels and frequencies, making the low price asynchronous motor suitable for international applications and diverse electrical infrastructure requirements.