Универсальные характеристики в различных промышленных применениях

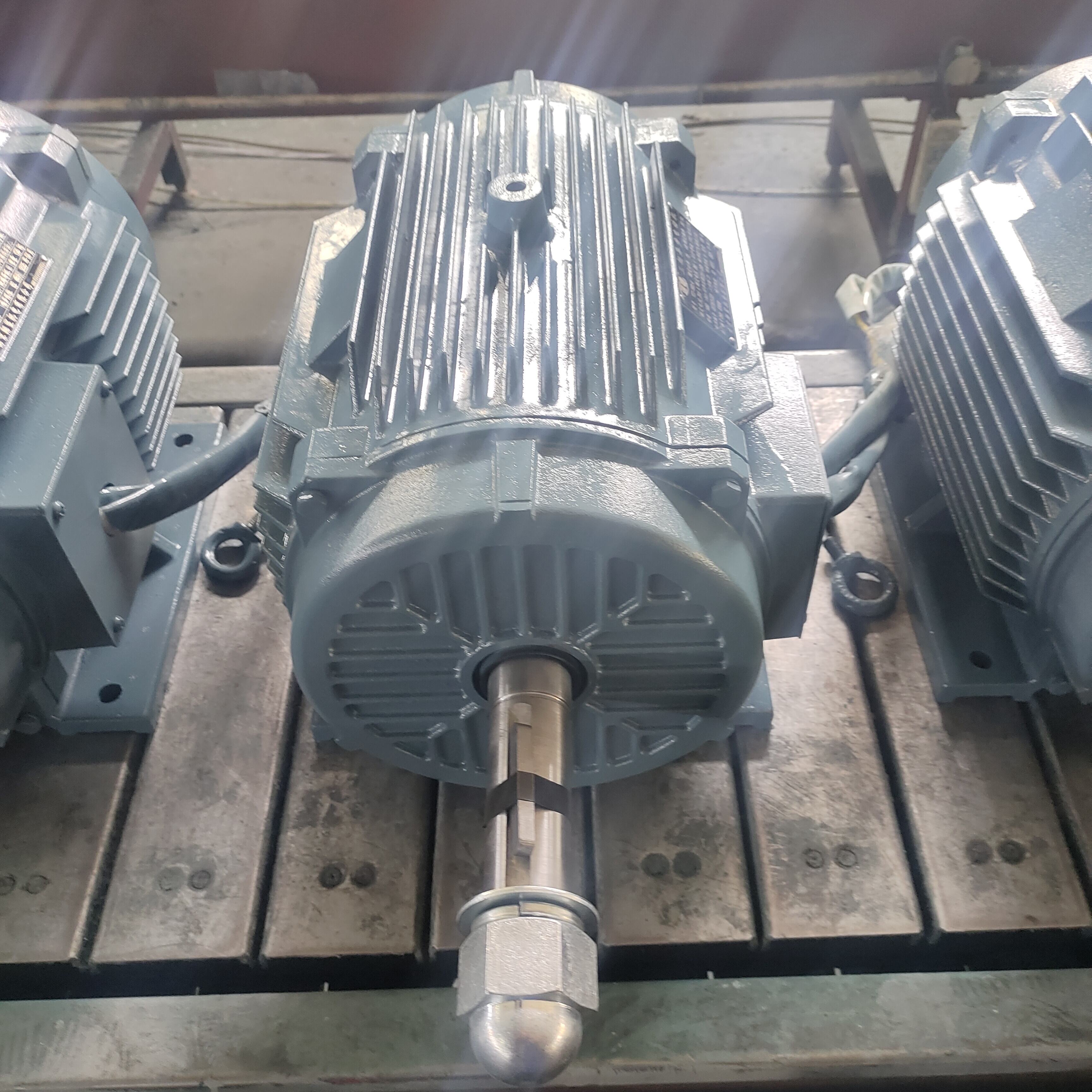

Универсальность недорогого асинхронного двигателя делает его незаменимым компонентом в многочисленных отраслях промышленности, демонстрируя адаптивность, которой не могут похвастаться многие другие технологии двигателей. Эта универсальность обусловлена способностью двигателя эффективно работать в широком диапазоне мощностей — от дробных лошадиных сил, подходящих для небольших механизмов, до крупных промышленных двигателей, способных выдерживать значительные нагрузки. Возможности регулирования скорости обеспечивают гибкость для приложений, требующих переменных рабочих скоростей, с простыми и экономичными методами управления, включая частотные преобразователи, переключение числа полюсов и системы регулирования напряжения. Двигатели отлично справляются с приложениями, требующими постоянной скорости, сохраняя стабильную угловую скорость независимо от незначительных колебаний нагрузки, что делает их идеальными для вентиляторов, насосов и конвейерных систем, где критически важна стабильная работа. Характеристики пуска позволяют работать с различными типами нагрузок — от приложений с низкой инерцией, требующих быстрого ускорения, до систем с высокой инерцией, которым необходимо постепенное наращивание скорости. Недорогой асинхронный двигатель демонстрирует исключительную производительность в режимах длительной работы, обеспечивая стабильную мощность в течение продолжительных периодов эксплуатации без снижения характеристик или потери эффективности. Возможности работы в повторно-кратковременных режимах позволяют этим двигателям справляться с приложениями, имеющими периодические циклы работы, автоматически адаптируясь к изменяющимся тепловым и механическим нагрузкам. Адаптация к окружающей среде позволяет использовать двигатели в различных условиях — от чистых производственных помещений до суровых промышленных условий с воздействием пыли, влаги, экстремальных температур и химических паров. Различные типы корпусов и степени защиты обеспечивают подходящие варианты для установки внутри и вне помещений, в опасных зонах и специализированных промышленных условиях. Возможности подбора под нагрузку позволяют правильно выбирать двигатель для конкретного применения, с различными характеристиками крутящего момента, доступными для соответствия разным требованиям механических нагрузок. Двигатели легко интегрируются в существующие промышленные системы управления, принимают стандартные управляющие сигналы и взаимодействуют с программируемыми логическими контроллерами, системами безопасности и автоматизированным производственным оборудованием. Гибкость монтажа предусматривает различные способы установки, конфигурации валов и методы подключения, что позволяет интегрировать их в установки с ограниченным пространством и в специализированные конструкции машин. Совместимость по питанию охватывает различные уровни напряжения и частоты, что делает недорогой асинхронный двигатель подходящим для международного применения и различных требований электрической инфраструктуры.