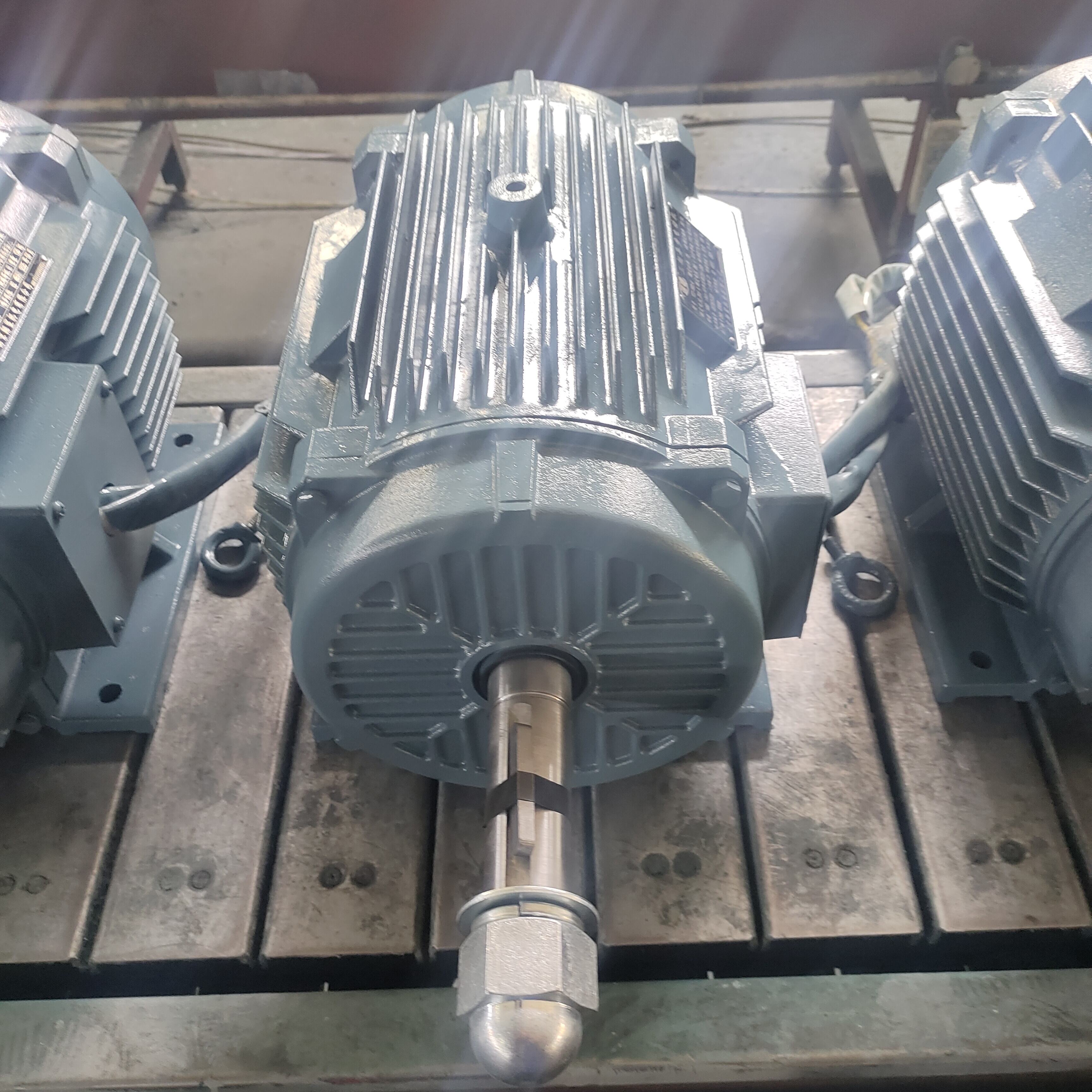

high quality asynchronous motor

The high quality asynchronous motor represents a pinnacle of electrical engineering innovation, delivering exceptional performance across diverse industrial and commercial applications. This sophisticated electrical machine operates on the fundamental principle of electromagnetic induction, where alternating current supplied to the stator windings creates a rotating magnetic field that induces current in the rotor, generating torque without direct electrical connection. The main functions of a high quality asynchronous motor encompass converting electrical energy into mechanical energy with remarkable efficiency, providing variable speed control capabilities, and maintaining consistent operation under varying load conditions. These motors excel in driving pumps, compressors, conveyor systems, and manufacturing equipment where reliable power transmission is essential. Technological features of premium asynchronous motors include advanced stator winding designs that minimize losses, optimized rotor configurations for enhanced starting torque, precision-engineered bearings for extended operational life, and sophisticated cooling systems that prevent overheating during continuous operation. Modern high quality asynchronous motors incorporate intelligent monitoring systems that provide real-time feedback on performance parameters, enabling predictive maintenance strategies. The robust construction typically features cast iron or aluminum housings designed to withstand harsh environmental conditions, while specialized insulation materials ensure safe operation at elevated temperatures. Applications span numerous industries including manufacturing, mining, agriculture, HVAC systems, and marine propulsion, where the high quality asynchronous motor proves indispensable for powering critical operations. These motors demonstrate exceptional versatility in handling both constant and variable load requirements, making them suitable for applications ranging from simple fan drives to complex automated production lines. The integration of advanced control systems allows for precise speed regulation, energy optimization, and seamless integration with modern automation protocols.