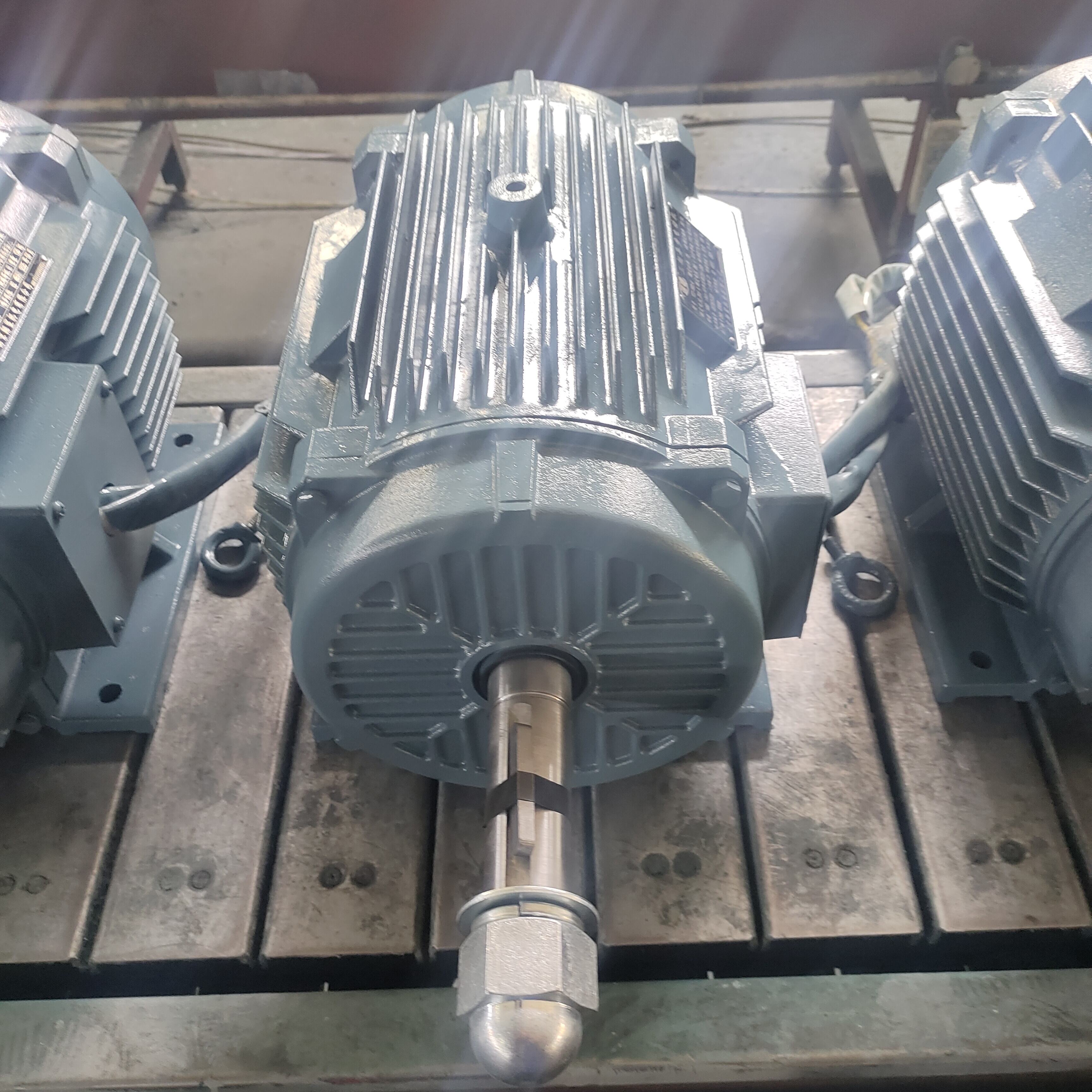

advanced asynchronous motor

The advanced asynchronous motor represents a pinnacle of modern electrical engineering, designed to deliver exceptional performance across diverse industrial applications. This sophisticated electrical machine operates on the principle of electromagnetic induction, where the rotating magnetic field in the stator induces current in the rotor, creating torque without direct electrical connection to the rotor windings. The advanced asynchronous motor incorporates cutting-edge materials, precision manufacturing techniques, and intelligent control systems that significantly enhance its operational capabilities compared to conventional motors. These motors feature high-grade silicon steel laminations that reduce core losses, premium insulation materials that extend service life, and optimized rotor designs that improve efficiency and reduce vibration. The technological architecture includes variable frequency drive compatibility, allowing precise speed control and energy optimization across different load conditions. Advanced thermal management systems ensure consistent performance even under demanding operational environments, while integrated sensor technologies provide real-time monitoring of critical parameters such as temperature, vibration, and current consumption. The main functions of the advanced asynchronous motor encompass power conversion from electrical to mechanical energy with superior efficiency ratings often exceeding 95 percent, providing reliable torque delivery across wide speed ranges, and maintaining consistent performance under varying load conditions. These motors excel in applications requiring precise speed control, high starting torque, and continuous operation cycles. Key technological features include enhanced rotor cage designs that minimize slip losses, advanced bearing systems that extend maintenance intervals, and sophisticated cooling mechanisms that prevent overheating during intensive operations. The advanced asynchronous motor finds extensive applications in manufacturing automation, conveyor systems, pump operations, fan installations, compressor drives, and renewable energy systems where reliability and efficiency are paramount considerations for long-term operational success.