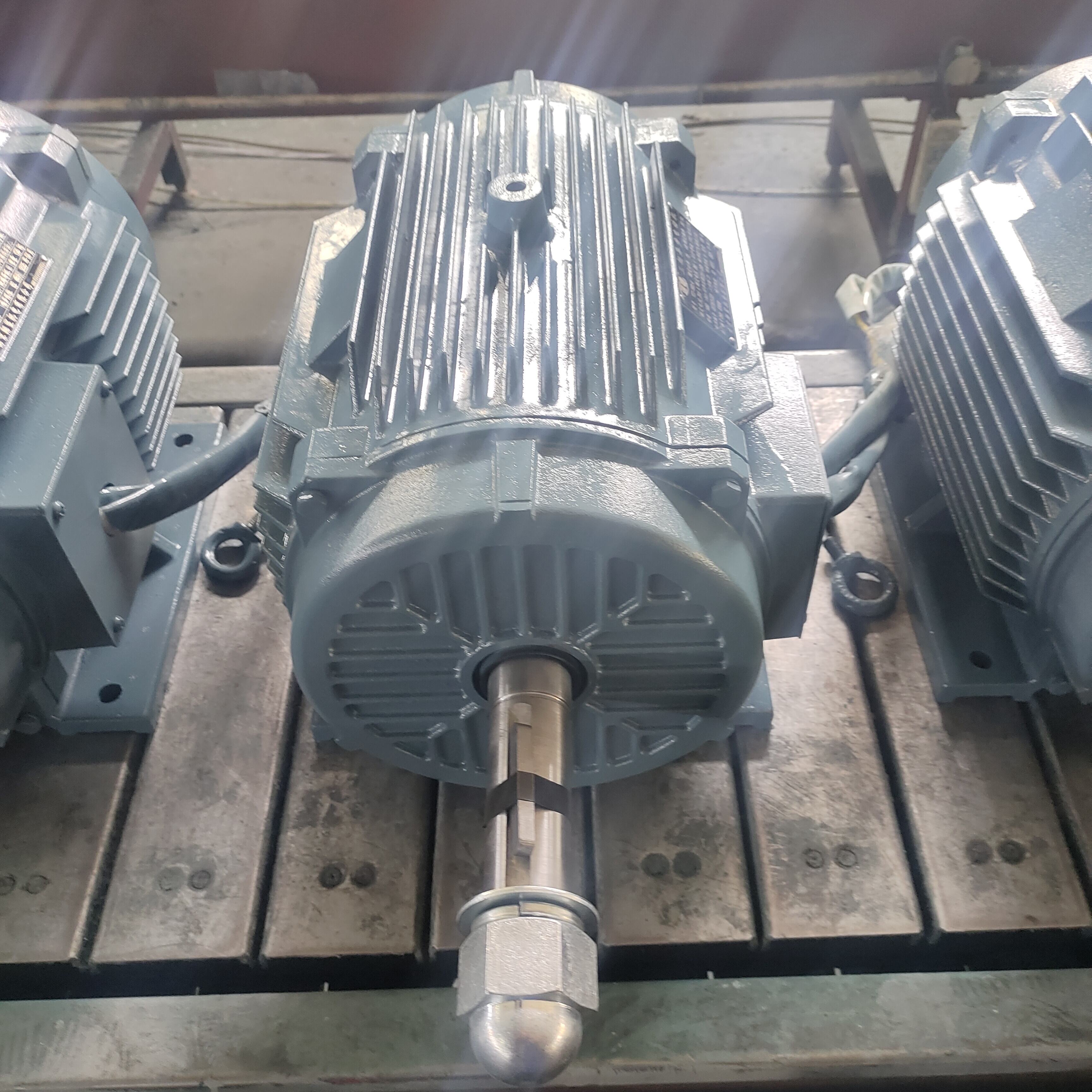

motor asincron de înaltă calitate

Motorul asincron de înaltă calitate reprezintă un apogeu al inovației în ingineria electrică, oferind o performanță excepțională în diverse aplicații industriale și comerciale. Această mașină electrică sofisticată funcționează pe baza principiului fundamental al inducției electromagnetice, unde curentul alternativ furnizat înfășurărilor statorului creează un câmp magnetic rotativ care induce un curent în rotor, generând cuplu fără o conexiune electrică directă. Funcțiile principale ale unui motor asincron de înaltă calitate includ conversia energiei electrice în energie mecanică cu o eficiență remarcabilă, posibilitatea de control al vitezei variabile și menținerea unei funcționări constante în condiții de sarcină variabilă. Aceste motoare se disting prin acționarea pompelor, compresoarelor, sistemelor de transport cu benzi, și echipamentelor de producție, unde transmiterea fiabilă a puterii este esențială. Caracteristicile tehnologice ale motoarelor asincrone premium includ proiectări avansate ale înfășurărilor statorului care minimizează pierderile, configurații ale rotorului optimizate pentru un cuplu de pornire crescut, rulmenți realizați cu precizie pentru o durată de viață operațională prelungită și sisteme rafinate de răcire care previn supraîncălzirea în timpul funcționării continue. Motoarele moderne de înaltă calitate integrează sisteme inteligente de monitorizare care oferă date în timp real despre parametrii de performanță, permițând strategii de întreținere predictivă. Construcția robustă include de obicei carcase din fontă sau aluminiu, concepute să reziste la condiții mediului dificile, în timp ce materialele speciale de izolație asigură funcționarea sigură la temperaturi ridicate. Aplicațiile acoperă numeroase industrii, inclusiv producția industrială, minerit, agricultură, sisteme HVAC și propulsia navală, unde motorul asincron de înaltă calitate se dovedește indispensabil pentru alimentarea operațiunilor critice. Aceste motoare demonstrează o versatilitate excepțională în gestionarea cerințelor de sarcină atât constante, cât și variabile, fiind potrivite pentru aplicații care variază de la acționarea simplă a ventilatoarelor până la linii complexe de producție automatizate. Integrarea sistemelor avansate de control permite reglarea precisă a vitezei, optimizarea consumului de energie și integrarea fluentă cu protocoalele moderne de automatizare.

![[YBBP80M1-8 - YBBP160L-8] [0,18-7,5kw] [0,2-10,2hp] MOTOR ASINCRON TRIFAZĂ RESISTENT LA FLAMEȚI](https://shopcdnpro.grainajz.com/category/405741/2986/fa575b66602ad08a4be3654adcf6c5fb/YBBP%E9%98%B2%E7%88%86%E5%8F%98%E9%A2%91%E4%B8%89%E7%9B%B8%E5%BC%82%E6%AD%A5%E7%94%B5%E5%8A%A8%E6%9C%BA.jpg.png)