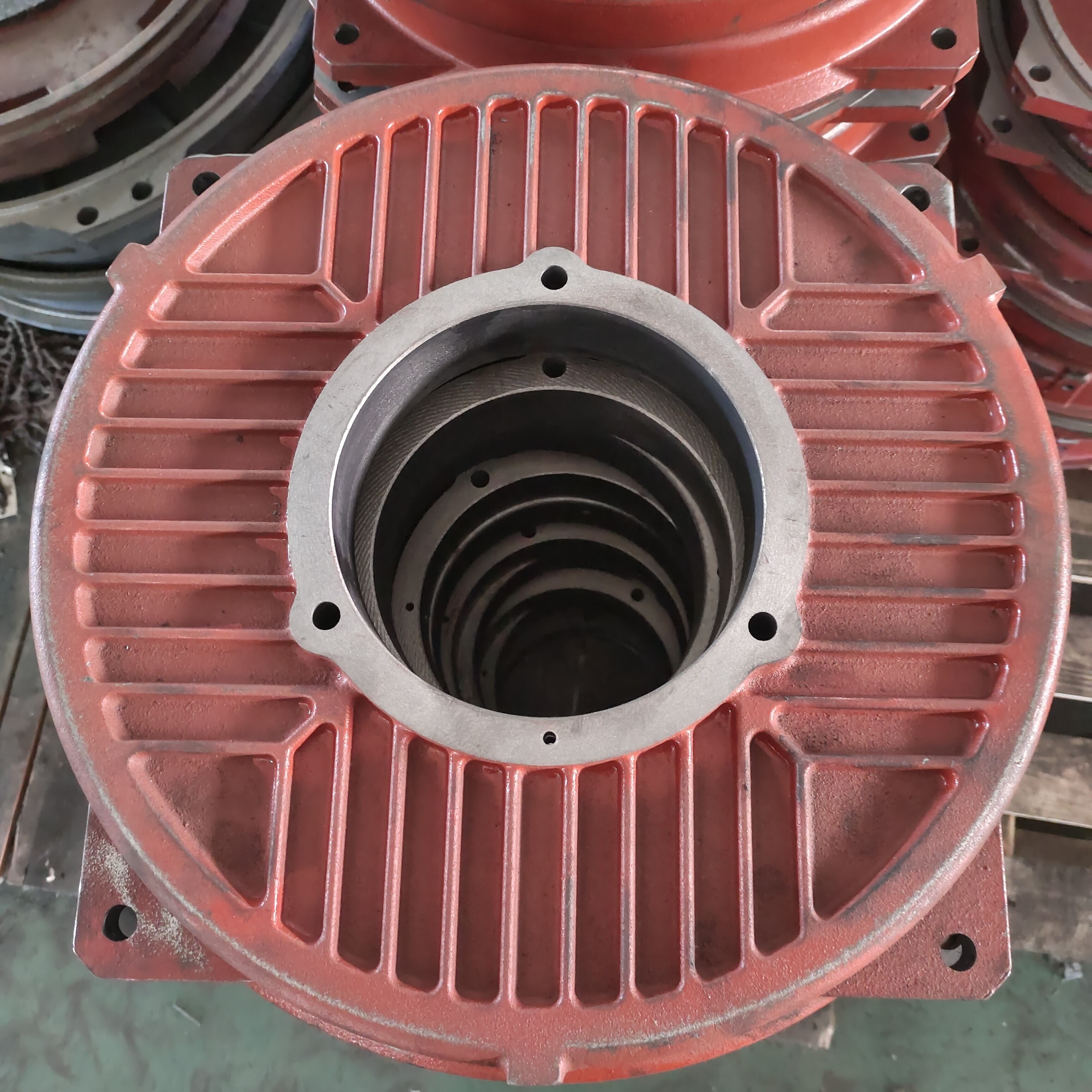

효율적인 엔드 플레이트

고효율 엔드 플레이트는 현대 산업 시스템에서 중요한 구성 요소로, 다양한 기계 응용 분야에서 최적의 성능과 신뢰성을 보장하는 종단 연결 지점 역할을 한다. 이 정교한 공학 솔루션은 배관 시스템, 압력 용기 및 산업 장비에서 마감 부재로 작동하며, 작동 효율성을 유지하면서도 안전한 밀폐를 제공한다. 고효율 엔드 플레이트는 구조적 완전성과 성능 최적화를 동시에 중시하는 고도화된 설계 방식으로 차별화된다. 고품질 소재와 정밀 공학 기술을 사용해 제조된 이 부품은 뛰어난 내구성을 제공하면서 유지보수 요구 사항을 최소화한다. 설계에는 응력을 표면 전체에 균등하게 분산시켜 국부적인 파손을 방지하고 수명을 연장시키는 전략적 보강 패턴이 포함되어 있다. 최신 고효율 엔드 플레이트 설계는 누출 위험을 제거하는 향상된 밀봉 기능을 갖추어 고압 조건에서도 시스템의 완전성을 확보한다. 고효율 엔드 플레이트의 기술적 우수성은 자동 설치 공정과의 호환성에도 나타나며, 이는 인건비와 설치 시간을 줄여준다. 제조 과정에서 적용되는 고급 표면 처리 기술은 우수한 부식 저항성을 제공하여 혹독한 환경 조건에서도 사용이 가능하게 한다. 고효율 엔드 플레이트 구조는 점검 및 유지보수 접근이 용이하여 시스템 가동을 방해하지 않고 정기적인 서비스 작업을 지원한다. 고효율 엔드 플레이트의 응용 분야는 석유 및 가스, 화학 공정, 수처리, 발전, 제조업 등 여러 산업에 걸쳐 있다. 석유화학 시설에서는 휘발성 물질의 안전한 밀폐와 함께 공정 효율성을 유지하는 데 이러한 부품이 사용된다. 수처리 플랜트는 여과 시스템의 신뢰성 있는 성능을 위해 고효율 엔드 플레이트 기술에 의존한다. 고효율 엔드 플레이트 설계의 다목적성 덕분에 다양한 압력 등급과 온도 사양에 대응할 수 있어 다양한 운전 조건에 유연하게 적응할 수 있다. 품질 보증 프로토콜을 통해 각 고효율 엔드 플레이트가 설치 전에 까다로운 산업 표준 및 규제 준수 요건을 충족하는지 확인한다.