Fejlett Anyagtechnológia és Kiváló Tartósság

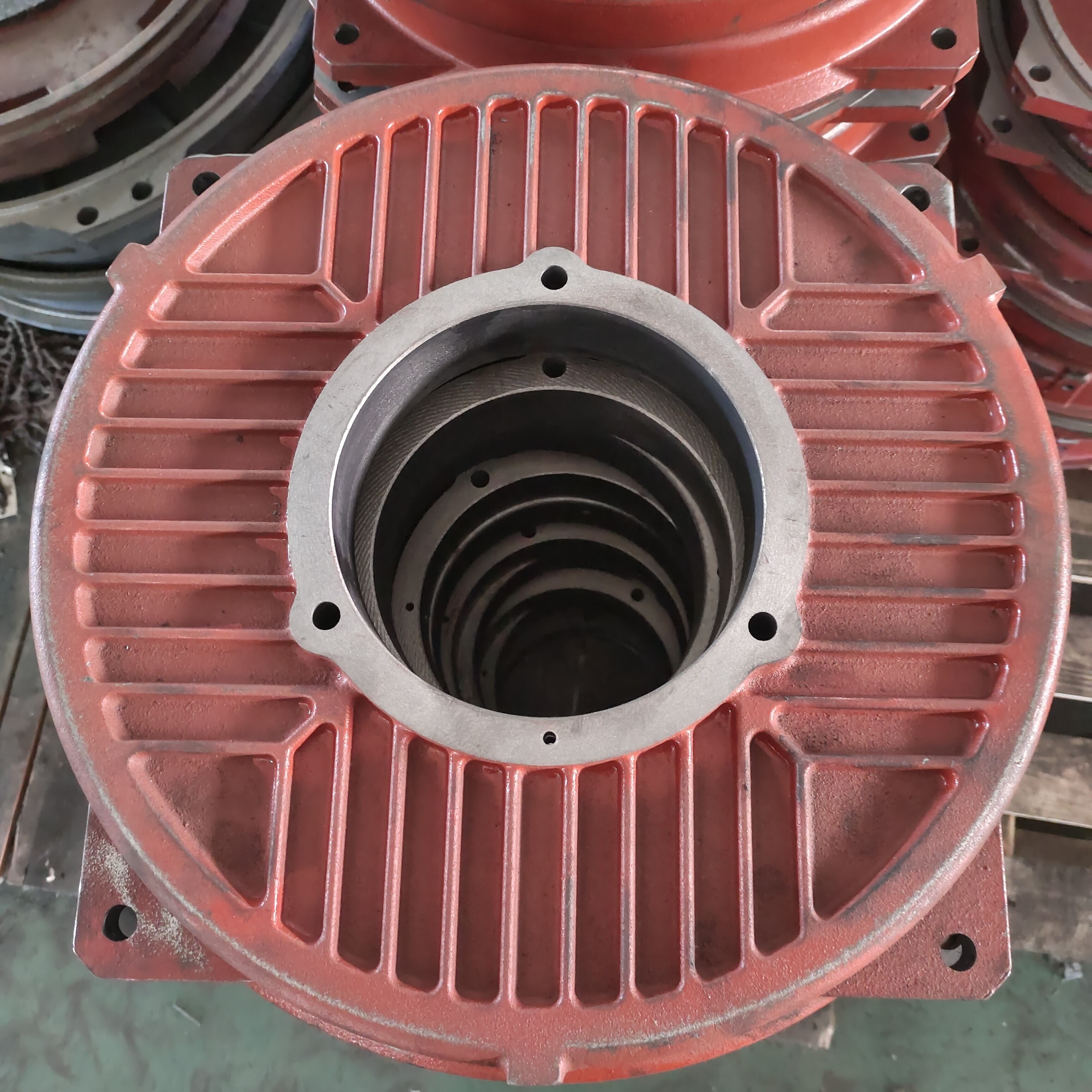

Az hatékony zárólemez a korszerű anyagtudomány és az előrehaladott fémtechnológia ötvözetét alkalmazza, hogy páratlan tartósságot és teljesítményt nyújtson igényes ipari környezetekben. Ennek a kiváló teljesítménynek az alapját a gondosan kiválasztott nagy minőségű ötvözetek képezik, amelyek ellenállnak a korróziónak, az eróziónak és a hőterhelésnek, miközben megőrzik szerkezeti integritásukat extrém üzemeltetési körülmények között. Az hatékony zárólemez kizárólagos hőkezelési eljárásokat alkalmaz, amelyek javítják az anyag tulajdonságait, így kiváló szilárdság-tömeg arányt és meghosszabbodott fáradási élettartamot eredményeznek. Ezek az előrehaladott anyagok szigorú tesztelési protokollokon esnek át, beleértve feszültségelemzést, korrózióállóság-elemzést és hőciklusos vizsgálatokat, biztosítva ezzel az alkatrész működési élettartama alatt az állandó teljesítményt. Az hatékony zárólemez gyártási folyamata precíziós megmunkálási technikákat alkalmaz, amelyek szoros tűréshatárokat és sima felületminőséget érnek el, hozzájárulva az optimális tömítési teljesítményhez és a súrlódási veszteségek csökkentéséhez. A felületelőkészítés speciális bevonatok felvitelét is magában foglalja, amelyek további védelmet nyújtanak a környezeti tényezőkkel szemben, mint például vegyi expozíció, hőmérsékletingadozás és mechanikai kopás. Az hatékony zárólemez tervezése stratégiai anyagelosztást tartalmaz, amely optimalizálja a feszültségkoncentrációs mintákat, megszüntetve az olyan gyenge pontokat, amelyek korai meghibásodáshoz vezethetnek. A gyártási folyamat során alkalmazott minőségirányítási intézkedések biztosítják, hogy minden hatékony zárólemez pontosan megfeleljen az előírt specifikációknak és teljesítményszabványoknak. Az anyagválasztási folyamat figyelembe veszi a hosszú távú teljesítményjellemzőket, így biztosítva, hogy az hatékony zárólemez működési képessége akár évek folyamatos használat után is megmaradjon. A fejlett roncsolásmentes vizsgálati módszerek belső anyagépszerűséget ellenőriznek, és bármilyen potenciális hibát detektálnak, mielőtt az alkatrészek üzembe kerülnének. Ez a komplex megközelítés az anyagtechnológiában és a minőségbiztosításban bizalmat ad a felhasználók számára a hatékony zárólemez telepítéseinek hosszú távú megbízhatóságában és költséghatékonyságában. A kiváló minőségű anyagokba és gyártási folyamatokba történő beruházás közvetlenül csökkentett karbantartási költségekben, meghosszabbodott cseréi időközökben és javult üzemeltetési megbízhatóságban nyilvánul meg a végfelhasználók számára.