Understanding the fundamental principles of electric motor technology becomes increasingly important as industrial automation continues to evolve. An asynchronous motor, also known as an induction motor, represents one of the most widely used electrical machines in modern industry. These motors operate on the principle of electromagnetic induction, where the rotor receives energy through magnetic field interaction rather than direct electrical connection. The reliability, efficiency, and cost-effectiveness of asynchronous motors make them indispensable across countless applications, from manufacturing processes to commercial HVAC systems.

The widespread adoption of these motors stems from their inherent design advantages and operational characteristics. Unlike synchronous motors that require precise timing mechanisms, asynchronous motors self-start and adapt to varying load conditions automatically. This adaptability, combined with minimal maintenance requirements, positions them as the preferred choice for numerous industrial applications. Engineers and facility managers increasingly rely on these motors to deliver consistent performance while maintaining operational efficiency across diverse working environments.

Fundamental Operating Principles

Electromagnetic Induction Theory

The core operating principle of an asynchronous motor relies on Faraday's law of electromagnetic induction. When alternating current flows through the stator windings, it creates a rotating magnetic field that moves around the motor's circumference. This rotating field induces currents in the rotor conductors, which in turn produce their own magnetic field. The interaction between these two magnetic fields generates the torque necessary to rotate the motor shaft.

The frequency of the rotating magnetic field depends directly on the supply frequency and the number of pole pairs in the motor design. For a standard 60 Hz supply with a four-pole motor, the synchronous speed reaches 1800 revolutions per minute. However, the actual rotor speed remains slightly lower than this synchronous speed, creating the characteristic slip that defines asynchronous operation. This slip percentage typically ranges from 2% to 5% under normal operating conditions.

Slip and Torque Characteristics

Slip represents the fundamental difference between synchronous speed and actual rotor speed, expressed as a percentage of synchronous speed. This slip enables the continuous induction of currents in the rotor, maintaining the electromagnetic forces necessary for rotation. As load increases, slip increases proportionally, allowing the motor to develop higher torque to meet mechanical demands.

The relationship between slip and torque follows a characteristic curve that defines motor performance under various operating conditions. At startup, high slip produces maximum torque, enabling the motor to overcome initial load inertia. As the motor accelerates and slip decreases, torque adjusts automatically to match the connected load requirements. This self-regulating behavior eliminates the need for complex control systems in many applications.

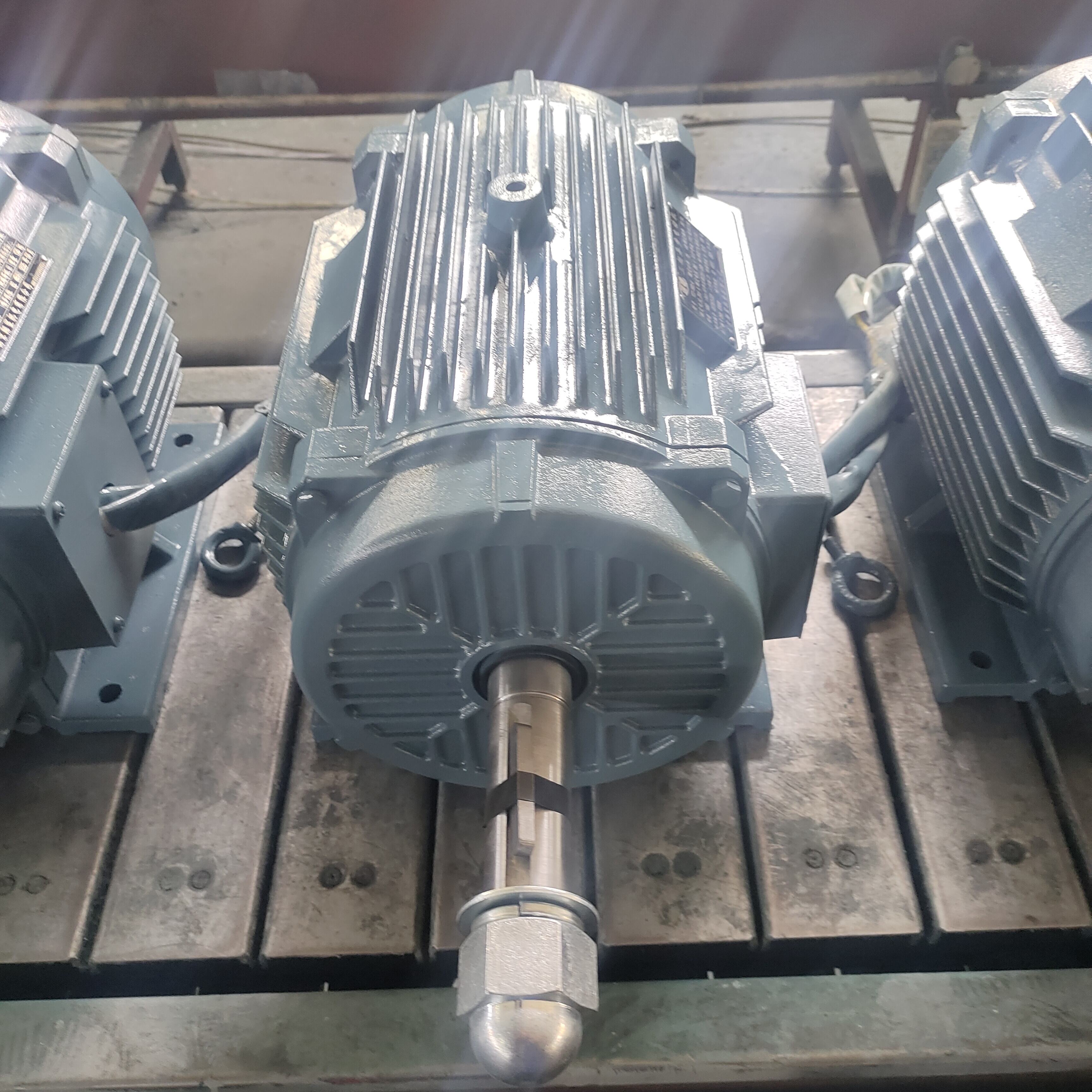

Construction and Design Elements

Stator Assembly Components

The stator forms the stationary outer portion of an asynchronous motor, housing the electromagnetic windings that create the rotating magnetic field. Constructed from laminated steel sheets to minimize eddy current losses, the stator core contains precisely machined slots that accommodate the copper or aluminum windings. These windings are arranged in specific patterns to ensure uniform magnetic field distribution and optimal motor performance.

Three-phase stator windings are positioned 120 degrees apart, creating a balanced electromagnetic system when connected to a three-phase power supply. The insulation system protecting these windings must withstand both electrical stress and thermal cycling throughout the motor's operational life. Modern insulation materials and application techniques ensure reliable performance across a wide temperature range while maintaining electrical integrity.

Rotor Design Variations

Two primary rotor designs dominate asynchronous motor construction: squirrel cage and wound rotor configurations. Squirrel cage rotors feature aluminum or copper bars embedded in rotor slots and connected by end rings, creating a simple, robust construction with excellent reliability characteristics. This design requires no external connections or maintenance, making it ideal for continuous duty applications.

Wound rotor designs incorporate actual windings similar to the stator, with connections brought out through slip rings for external circuit integration. This configuration allows for variable resistance insertion during startup, providing enhanced torque characteristics and speed control capabilities. While more complex than squirrel cage designs, wound rotors offer superior performance in applications requiring high starting torque or speed variation.

Performance Characteristics and Efficiency

Speed-Torque Relationships

The speed-torque curve of an asynchronous motor reveals distinct operating regions that define motor behavior under different load conditions. The starting torque region shows high torque production at zero speed, enabling motors to overcome initial load inertia. As speed increases, torque typically decreases until reaching the breakdown point, where maximum torque occurs before entering the unstable operating region.

Understanding these characteristics enables proper motor selection for specific applications. High starting torque applications, such as conveyors or compressors, require motors with favorable low-speed torque characteristics. Conversely, centrifugal loads like fans and pumps match well with motors having rising torque curves that align with quadratic load increases.

Energy Efficiency Considerations

Modern asynchronous motor designs achieve remarkable efficiency levels through advanced materials and optimized construction techniques. Premium efficiency motors incorporate low-loss electrical steel, optimized air gap dimensions, and precision manufacturing to minimize energy waste. These improvements translate directly into reduced operating costs and environmental impact over the motor's service life.

Efficiency ratings vary with load conditions, typically peaking around 75% to 100% of rated load. Operating motors significantly below their rated capacity results in decreased efficiency and poor power factor performance. Proper motor sizing ensures optimal efficiency while maintaining adequate service factor for occasional overload conditions. Variable frequency drives can further enhance system efficiency by matching motor speed to actual load requirements.

Industrial Applications and Use Cases

Manufacturing and Process Industries

Manufacturing facilities extensively utilize asynchronous motors for driving production equipment, from conveyor systems to machine tools. Their ability to provide consistent torque across varying speed ranges makes them suitable for applications requiring precise motion control. Process industries rely on these motors for pumps, compressors, and fans that maintain critical system parameters such as pressure, flow, and temperature.

The robust construction of asynchronous motors enables operation in challenging industrial environments, including exposure to dust, moisture, and temperature extremes. Specialized enclosure designs protect internal components while maintaining heat dissipation capabilities. This durability reduces maintenance requirements and ensures reliable operation in critical production processes where downtime carries significant economic consequences.

HVAC and Building Systems

Commercial and residential HVAC systems depend heavily on asynchronous motors for air handling units, cooling towers, and circulation pumps. The variable load characteristics of these applications align well with the natural speed-torque characteristics of induction motors. Energy efficiency regulations increasingly drive the adoption of premium efficiency motors in these applications, supporting sustainability goals while reducing operational expenses.

Building automation systems integrate asynchronous motors with variable frequency drives to optimize energy consumption based on actual demand. This combination enables precise control of air flow, water circulation, and other building systems while maintaining occupant comfort. The long service life and minimal maintenance requirements of these motors contribute to reduced lifecycle costs in building operations.

Maintenance and Troubleshooting

Preventive Maintenance Strategies

Effective maintenance programs for asynchronous motors focus on monitoring key parameters that indicate developing problems before catastrophic failures occur. Vibration analysis reveals bearing wear, rotor imbalance, or mechanical misalignment issues that can damage motor components if left unaddressed. Thermal monitoring through infrared scanning identifies hot spots caused by electrical problems or restricted cooling air flow.

Regular electrical testing includes insulation resistance measurements, current balance verification, and power quality analysis. These tests detect winding deterioration, connection problems, and supply voltage issues that affect motor performance and reliability. Establishing baseline measurements during initial installation provides reference points for trending analysis and predictive maintenance scheduling.

Common Failure Modes and Solutions

Bearing failures represent the most common cause of asynchronous motor problems, typically resulting from inadequate lubrication, contamination, or excessive loading conditions. Implementing proper lubrication schedules and monitoring bearing temperatures prevents most bearing-related failures. When bearing replacement becomes necessary, precision installation techniques ensure proper fit and alignment for extended service life.

Winding failures often stem from thermal stress, moisture ingress, or voltage transients that damage insulation systems. Environmental protection through proper enclosure selection and regular inspection prevents many winding problems. When rewinding becomes necessary, modern insulation materials and application techniques can improve motor reliability and extend service life beyond original specifications.

Future Developments and Technology Trends

Smart Motor Integration

The integration of intelligent monitoring systems transforms traditional asynchronous motors into smart devices capable of self-diagnosis and performance optimization. Embedded sensors monitor temperature, vibration, and electrical parameters continuously, transmitting data to maintenance management systems for analysis. This connectivity enables predictive maintenance strategies that reduce unplanned downtime while optimizing maintenance resource allocation.

Artificial intelligence algorithms analyze historical performance data to identify patterns that precede failure events. This capability allows maintenance teams to schedule interventions during planned shutdowns, minimizing production disruptions. The combination of motor intelligence and advanced analytics represents a significant advancement in industrial asset management strategies.

Efficiency and Environmental Impact

Ongoing research into advanced materials and manufacturing techniques continues to improve asynchronous motor efficiency and reduce environmental impact. Rare earth-free rotor designs eliminate dependence on environmentally sensitive materials while maintaining performance characteristics. Manufacturing process improvements reduce energy consumption during production and enable motor recycling at end of life.

Regulatory developments worldwide increasingly mandate higher efficiency standards for industrial motors, driving innovation in design and materials. These requirements align with global sustainability goals while creating economic incentives for users to upgrade existing installations. The convergence of regulatory pressure and technological advancement accelerates the adoption of next-generation motor technologies across industrial applications.

FAQ

What makes an asynchronous motor different from other motor types

An asynchronous motor operates without requiring synchronized timing between the rotor and stator magnetic fields, unlike synchronous motors that maintain exact speed relationships with supply frequency. The rotor speed naturally lags behind the rotating magnetic field, creating slip that enables continuous torque production. This design eliminates the need for complex timing circuits or permanent magnets, resulting in simpler construction and lower maintenance requirements compared to other motor technologies.

How do you determine the correct size asynchronous motor for an application

Proper motor sizing requires analyzing the load characteristics, including starting torque requirements, running torque demands, and speed variations throughout the operating cycle. Calculate the power requirements at different operating points and select a motor with adequate capacity while considering service factors for occasional overloads. Environmental conditions, duty cycle, and efficiency requirements also influence motor selection to ensure optimal performance and longevity in the specific application.

Can asynchronous motors operate at variable speeds

Yes, asynchronous motors can operate at variable speeds when connected to variable frequency drives that modify the supply frequency and voltage. This combination provides precise speed control while maintaining efficient operation across a wide speed range. The motor speed changes proportionally with supply frequency, enabling applications requiring variable flow, pressure, or throughput without mechanical speed reduction devices.

What are the typical maintenance requirements for asynchronous motors

Routine maintenance includes bearing lubrication according to manufacturer schedules, regular cleaning to prevent dust accumulation, and periodic electrical testing to monitor insulation condition. Vibration monitoring and thermal scanning help detect developing problems before failures occur. Most asynchronous motors require minimal maintenance compared to other motor types, with bearing replacement being the most common service requirement after several years of operation depending on operating conditions and load factors.