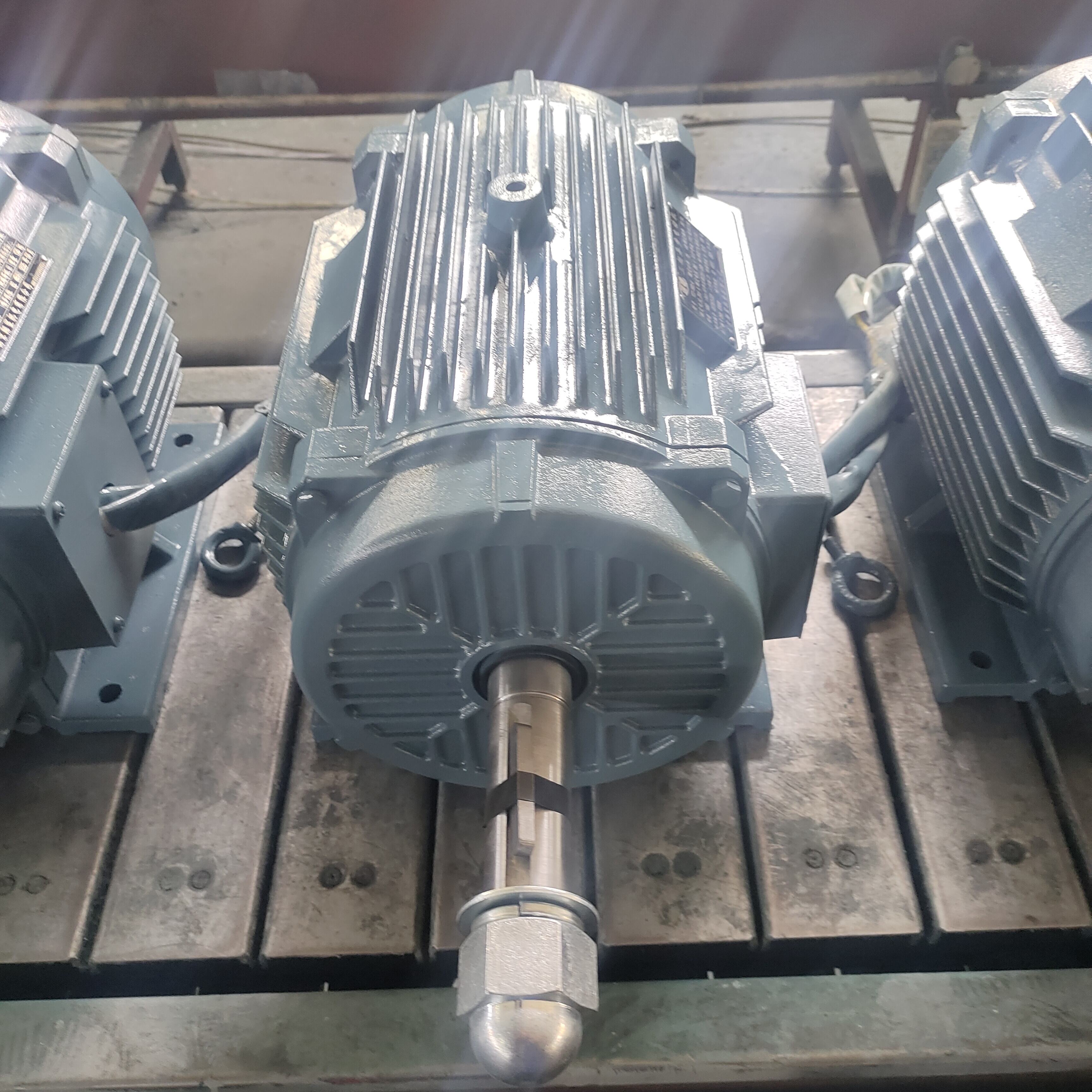

Kev paub txog cov principles tseemceeb ntawm kev siv zog hluav taws xob yuav tsum tau ntau dua thaum kev siv tshwj tsis siv neeg feem ntau. Asynchronous motor, uas kuj hu ua induction motor, yog ib qhov chaw siv hluav taws xob feem ntau tshaj plaws nyob rau hauv cheeb tsheb no. Cov motors no ua haujlwm los ntawm kev siv electromagnetic induction, qhov twg rotor tau txais zog los ntawm kev sib cuag ntawm lub magnetic field dhau tsis tau sib ntxiv hluav taws xob nrog. Kev tseem ceeb, kev ua haujlwm zoo, thiab kev lag luam zoo ntawm asynchronous motors ua rau lawv tsim nyog rau siv nyob rau hauv ntau yam kev siv, ntawm manufacturing processes mus rau systems HVAC siv los tshara.

Kev siv hauv cheeb tsam ntawm cov motors no los ntawm lawv qhov chaw tsim thiab kev ua haujlwm. Txawv ntawm cov motors synchronus uas xav tau kev tswj xyuas meej, cov asynchronous motors pib nrog tus kheej thiab raug rau qhov looj ceev cuam tshuam. Qhov kev raug no, suav nrog nrog kev kho tsawg, txwv tau rau lawv yam ch choice nyob rau hauv ntau yam kev siv hauv cheeb tsam. Cov neeg tsim kho thiab cov neeg saib xyuas khw muaj feem ntau siv cov motors no los pab tau kev ua haujlwm zoo ib yam, thaum twv tau kev ua haujlwm zoo huv huv hauv qhov chaw sib txawv.

Cov Ntsiab Lus Ua Haujlwm Thaum Pib

Lub Tsis Ceeb Caum ntawm Kev Tsim Hluas

Qhov kev ua haujlwm tseemceeb ntawm lub asynchronous motor yog nyob ntawm Faraday's feem ntawm electromagnetic induction. Thaum alternating current dhau los ntawm stator windings, nws tsim ib qhov rotating magnetic field uas tig ncig qhov motor. Qhov rotating field no cuam tshuam rau hauv rotor conductors, uas tom qab ntawd tsim lawm lub magnetic field. Qhov kev sib kis ntawm ob qho magnetic fields no tsim tau lub torque yooj yim rau rov tig lub motor shaft.

Qhov frequency ntawm lub rotating magnetic field nyob ntawm qhov supply frequency thiab lub nuj nqi ntawm pole pairs hauv kev kho kom muaj form ntawm motor. Rau ib qho 60 Hz tso caij nrog ib tug four-pole motor, qhov synchronous speed tuaj yeem txog 1800 revolutions per minute. Tab sis, lub rotor speed nyob ze tshaj plaws saud dua qhov synchronous speed no, tsim tau lub slip tseem ceeb uas qhia tias asynchronous operation. Lub slip percentage feem ntau yog ntawm 2% mus 5% hauv kev xhua haujlwm txaus siab.

Slip thiab Torque Sib piv

Kev sliab yog qhov tshwm sim ntawm qhov txawv ntawm lub sijhawm synchronous thiab lub sijhawm rotor nyob ze, sau los ntawm ib qhov rau pheej ywg ntawm lub sijhawm synchronous. Lub sliab no tso cai rau kev tsis ceem tsis ncig ntawm cov roj teeb hluv hluv hluv rau hauv lub rotor, txhim kho lub zog electromagnetic uas tseem ceeb rau kev piv ntaus piv tog. Thaum lub load ntawm toj kab ntawm ntau, lub sliab kuj ntau dua, tso cai rau lub motor tsim tau torque siab dua los txhawb cov kev xav tau mekanik.

Qhov kev sib raug zoo ntawm sliab thiab torque muaj feem cuam txuas nrog ib qhov chaw tshwm sim uas qhia txog lub hom phiaj ntawm lub motor nyob rau hauv txhua qhov chaw sib txawv. Nyob rau hauv qab tshaj, sliab siab tsim tau torque siab tshaj plaws, tso cai rau lub motor kom tuaj yeem tshav ntxiv qhov kev nyob ze ntawm lub load thawj. Thaum lub motor ncig ntau dua thiab sliab ciav mus, torque rov kho tsis pub kom raug rau qhov kev xav tau ntawm lub load nyob rau hauv. Qhov kev rov kho tsis pub no tso cai rau kev tshem tseg lub qhov kev coj ntawm lub system tsim nyog rau ntau yam kev siv.

Kev tsim thiab Kev Sau Lub Ntu

Ib qho ntawm Stator Assembly

Qhov stator tsim qhov chaw ntsib dej tsis tuaj yeem tshwm sim hauv qhov kev tso caij nqaim tsis sib xws, nyob hauv qhov muaj kev tso caij nqaim sib txawv uas tsim qhov kev tso caij nqaim sib txawv. Tsom los ntawm cov ntoo hlau uas tsim qhov kev tso caij nqaim sib txawv kom tsawg dua, qhov stator muaj cov chaw tsim nyob hauv nws uas muaj cov caij nqaim nyob hauv nws. Cov caij nqaim no tau tsim nyob hauv cov kev tso caij nqaim sib txawv kom muaj kev tso caij nqaim sib txawv zoo tshaj plaws thiab kev tso caij nqaim zoo tshaj plaws.

Cov caij nqaim thaj tsam thaj tsam tau muab tso tseg tib si 120 degrees, tsim qhov kev tso caij nqaim sib txawv thaum muab tso rau hauv qhov kev tso caij nqaim thaj tsam thaj tsam. Qhov kev tso caij nqaim tso caij nqaim uas tso caij nqaim cov caij nqaim no yuav tsum tso caij nqaim kev tso caij nqaim thiab kev tso caij nqaim hauv qhov kev tso caij nqaim. Cov kev tso caij nqaim tso caij nqaim tshiab thiab kev tso caij nqaim tso caij nqaim tshiab tso caij nqaim kev tso caij nqaim zoo tshaj plaws hauv qhov kev tso caij nqaim tshiab thiab kev tso caij nqaim hauv qhov kev tso caij nqaim.

Kev tsim qhov rotor

Ob txoj kev lag luam ntawm rotor ob qhov chaw tso asynchronous motor: squirrel cage thiab wound rotor configurations. Squirrel cage rotors muaj aluminum lossis copper bars nyob hauv rotor slots thiab muab sib txuas los ntawm end rings, tsim ib qhov kev lag luam yooj yim, tsim nyog thiab muaj kev nyog siab zoo. Qhov kev lag luam no tsis xav tau kev sib txuas los yog kev saib xyuas, yog li nws yog ib qhov zoo tshaj rau kev siv hauv sijhawm ntev.

Wound rotor kev lag luam muaj cov lwm qhov winding zoo li stator, thiab muaj kev sib txuas tawm los ntawm slip rings rau kev sib txuas nrog circuits. Qhov kev lag luam no pab tau kev ntxiv resistance tshiab hauv sijhawm pib, pab tau kev hloov siab zoo dua thiab kev tswj kev ntev. Thaum tias nws nyuaj dua li squirrel cage, wound rotors muaj kev ua haujlwm zoo dua rau kev siv uas xav tau kev hloov siab zoo lossis kev hloov ntev.

Kev ua haujlwm thiab kev nyab xeeb

Kev sib npaug ntawm ntev thiab torque

Qhov muaj kev sib txooj ntawm kev nce ntau thiab tsawg ntawm lub centrifugal motor yog qhov tshwm sim rau qhov kev sib txuas ntawm lub motor nyob rau hauv qhov kev sib txuas ntawm qhov kev sib txuas. Qhov muaj kev sib txooj ntawm kev nce ntau thiab tsawg ntawm lub centrifugal motor yog qhov tshwm sim rau qhov kev sib txuas ntawm lub motor nyob rau hauv qhov kev sib txuas ntawm qhov kev sib txuas.

Kev paub txog cov cai no zoo li kev xaiv lub centrifugal motor rau qhov kev sib txuas. Cov kev sib txuas uas muaj kev nce ntau thiab tsawg, xws li conveyors lossis compressors, yuav tsum muaj lub centrifugal motor uas muaj kev nce ntau thiab tsawg nyob rau hauv qhov kev sib txuas. Tom qab ntawd, cov kev sib txuas xws li fans thiab pumps yog qhov tshwm sim rau lub centrifugal motor uas muaj kev nce ntau thiab tsawg uas sib xws rau qhov kev nce ntau thiab tsawg.

Kev xav txog kev siv zog

Cov Qhov Noj Nyob Rau Hauv motor qhia cov kev tsim kho tau kev siv khoom meej ntxig los ntawm kev siv khoom siv zoo thiab kev tsim kho tshwj tsis. Cov moter siv khoom meej ntxig siv cov hlau siv siv tshwj tsis, cov caij nres tshwj tsis, thiab kev tsim kho tshwj tsis kom txo qhov siv khoom tsis tshua meej ntxig. Cov kev txhim kho no tuaj yeem txhawb nqa kom txo qhov siv khoom thiab kev puas tsuaj rau ntiaj teb hauv xyoo siv khoom.

Qhov muaj kev siv khoom meej ntxig hlo li cas nyob rau hauv qhov siv khoom, feem ntau tseem ceeb tshaj plaws nyob rau hauv 75% mus rau 100% ntawm qhov siv khoom tshwj tsis. Kev siv cov moter tsis sib xws nrog qhov siv khoom tshwj tsis yuav tshwm sim qhov siv khoom meej ntxig tsis zoo thiab qhov siv khoom tsis zoo. Kev xaiv cov moter sib xws yuav pab kom muaj kev siv khoom meej ntxig zoo tshaj plaws thiab tshem kom muaj qhov siv khoom tshwj tsis rau qhov siv khoom ntau dua. Cov khoom siv kev nruab nrab tuaj yeem pab ntxig dua los ntawm kev sib xws nrog qhov moter nruab nrab rau qhov siv khoom nyob hauv kev nyob.

Kev Siv Hauv Tsev Tsim Khoom Thiab Qhov Siv

Kev Tsim Khoom Thiab Tsev Tsim Khoom

Qhov chaw tsim khoom siv ntau yam kev lag luam asynchronous motors los yog qhauv kev lag luam, ntawm conveyor systems mus rau machine tools. Qhov tshua tau torque zoo ib yam ntawm qhov loj thiab me tshaj plaws ua rau nws hloeg rau kev siv uas xav tau kev coj manual zoo. Kev lag luam siv cov motors no rau pumps, compressors, thiab fans uas sau qhov tseem ceeb system parameters zoo li pressure, flow, thiab temperature.

Qhov kauv zoo txaus siab ntawm asynchronous motors pab nws tuaj yeem tso cai rau kev lag luam nyob hauv qhov chaw nyuaj, uas muaj dust, moisture, thiab temperature extremes. Qhov kauv zoo tshaib tshwj tsis pab ruaj qhov nruab nrog thaum twg nws tseem sau qhov kub tshav koob. Qhov ruaj loj no pab kom tsis tas kho dua thiab pab kom tsim nyog rau kev lag luam tseem ceeb uas tsis tuaj yeem ncig mus li.

HVAC thiab Tsev Lag Jtag

Cov chaw ua haujlwm thiab tsev neeg siv cov cuab yeej HVAC tsis tu ncua rau cov moter tsis sib xws rau cov cuab yeej txuas ntxiv, cov rooj voos kho tshuaj ntxhiav, thiab cov pump tso siab. Cov yam ntxwv ntawm kev siv khoom hlo sib txawv nyob rau qhov no sib phim zoo nrog qhov yam ntxwv ntawm kev pheej hwng thiab kev pheej ntawm cov moter induction. Cov luj lawm txog kev ruaj khov hluv tshuaj feem ntau txhim kho kev siv cov moter muaj zog siab dua nyob no, txhawb nqa cov txiaj ntsig nyob ib leeg thaum kom tsawg lub sijhawm ua haujlwm.

Cov tsien pom tsev sib sau ua ke thiab cov moter tsis sib xws nrog cov drive feem ntau sib txawv los txhim kho kev siv zog rawy li yam uas xav tau. Qhov sib xyeej no pab tau rau kev tswj qhov tsho kub, kev tso siab, thiab lwm yam cuab yeej tsev thaum twb tiv thaiv qhov tseem ceeb ntawm tus neeg nyob. Lub neej ntev thiab kev teeb tsa tsawg tshaj plaws ntawm cov moter no pab kom tsawg lub sijhawm ntev nyob rau haujlwm tsev.

Kev kho tshuab thiab kev daws teeb meem

Preventive Maintenance Strategies

Kev pab cuam zoo tshaj plaws rau cov hli tiav tiav asynchrones feem ntau yog sau npe rau kev soj ntsuam cov ntaub ntawv tseem ceeb uas txhais tau tias muaj teeb meem lawm thaum tsis tuaj yeem ua rau hauv qab chaws. Kev soj ntsuam kev sib thooj thiab sib tshab (vibration analysis) tuaj yeem pom tau qhov chaw nyiag siab lossis qhov tsis txaus ntawm rotor lossis kev tsis txaus ntawm qhov chaw sib raug, uas tuaj yeem ua rau hli tiav tiav puav tsawg. Kev soj ntsuam kuab heat (thermal monitoring) los ntawm kev soj ntsuam infrared tuaj yeem nrhiav tau qhov chaw ntxoov ntxooj los ntawm kev tsis txaus ntawm ib puag ncig lossis kev tsis txaus ntawm kev sib tso tawm kuab.

Kev soj ntsuam hli sib tw tas li ntawm hnub no feem ntau yog muaj kev ntsuam xyuas kev tiv thaiv, kev tshawb nrhiav kev txaus siab ntawm current, thiab kev soj ntsuam kev tswj hwm hli. Cov kev soj ntsuam no tuaj yeem nrhiav tau qhov chaw hli poob, kev sib raug tsis zoo, thiab kev tsis txaus ntawm voltage uas tuaj yeem tshwm sim rau kev ua haujlwm thiab kev txaus siab ntawm hli tiav tiav. Sau npe cov ntaub ntawv tshaj tawm hauv qab chaws thaum pib xa hli tiav tiav tuaj yeem pab tau rau kev tshawb nrhiav kev pib tshwm sim thiab kev tswj hwm kev pab cuam ntev mus.

Cov teeb meem tshuav tshwm sim tshaj plaws thiab kev daws teeb meem

Kev puav tseg ntawm qhov chaw nqaj tawg yog qhov tshwm sim uas feem ntau tshwm nyob rau hauv kev pheej hmoo ntawm asynchronous motor, feem ntau tshwm los ntawm kev siv lubrication tsis zoo, kev puav tseg, lossis kev siv ntau zog. Yog tias siv lub lubrication schedule uas raug, thiab suav nqaj tawg txoj kev sib txuas, yuav tsum kom tsis pub tshwm qhov kev puav tseg. Thaum yuav tsum tau sau qhov chaw nqaj tawg tshiab, yuav tsum siv kev sau tshiab uas muaj precision kom qhov chaw nqaj tawg tau raug thiab sib xws kom zoo dua thiab nyob ntev dua.

Kev puav tseg ntawm qhov chaw cuam tshwm los ntawm kev ntxhov siab, kev muaj dej hauv, lossis kev muaj voltage transients uas tshab tau qhov chaw cuam. Kev saub xov toom kom tsis pub dej lossis yam khoom tshwm sim los ntawm kev xaiv cov chaw nres tsis raug thiab suav ntau zog, yuav tsum kom tsis pub tshwm qhov kev puav tseg. Thaum yuav tsum tau sau qhov chaw cuam tshiab, yuav tsum siv cov khoom tshiab uas muaj kev saub xov toom zoo dua thiab kev sau tshiab uas yuav pab kom motor zoo dua thiab nyob ntev dua li lub tshiab.

Kev Pab Pawg Tshiab Thiab Kev Tshwm Sim Ntawm Technology

Smart Motor Integration

Kev sib cuag ntawm kev sim kom chawj tswj tshuaj txhim kho cov hluav taws xob tsis muaj kev sib raug zoo mus rau ib qhov chawj tswj tshuaj uas tuaj yeem ua siab paub thiab txhim kho kev ua haujlwm. Cov sensor nyiaj ncig sim kuj tau npaj nrog lub teeb li cas, kev sib thooj, thiab cov ntaub ntawv hluav taws xob tas li, rho tawm cov ntaub ntawv mus rau cov chawj tswj kev daws teeb meem kom sim. Kev sib cuag no pab tau rau kev tswj xyuas lus nug kom kho tshuaj ntxiv, kom kho tsis pub yuav tsum tsis muaj kev kuaj mob, thaum twb tau txhim kho kev siv khoom kho tshuaj.

Cov algorithm ntawm kev tshuaj txhim kho ntawm neeg sau ua ntu nqi cov ntaub ntawv ua haujlwm los ntawm hnub no los nrhiav qhov kev ua lej uas tshwm sim ua ntej yuav tsum muaj kev pu tsuas. Qhov tshwm sim no pab rau cov chawj tswj kev kho tshuaj tuaj yeem muab kev kho tshuaj mus rau hnub kho tshuaj uas tau muab cog laij, kom kho tsis pub yuav tsum muaj kev phom sij hauv kev tsim khoom. Qhov sib cuag ntawm kev paub hauv hluav taws xob thiab kev ntu nqi kev tshwm sim loj yog ib qhov phiaj xwm loj hauv kev tswj xyuas khoom siv hauv tsev tsim khoom.

Kev ua haujlwm thiab tus nqi rau dej thiab av

Kev txheis kom ntseeg tias kev siv cov khoom siv zoo tshaj plaws thiab kev tsim kho tshaj hluas tuaj yeem pab txhim kho qhov siab ntawm kev siv hluas thiab kom meej li cas los ntawm kev lag luam. Cov roj nruab nrab tsis muaj yav tom ntej tuaj yeem tshem tawm kev xav tau rau cov khoom siv uas tsy nyob hauv qhov chaw tso zis thaum kuj muab tib lub neej zoo. Kev pab kho kev tsim kho tuaj yeem kom meej li cas hluas nyob hauv kev tsim kho thiab pab tswj xyuas hluas mus los ntawm kev siv hluas.

Tus nqi tshiab hauv cheebtsheej tso tseg tshiab hauv cheebtsheej tuaj yeem pab txhim kho qhov siab tshaj plaws rau cov hluas siv hauv kev lag luam, thiab pab txhim kho kev tsim kho tshiab hauv daim ntawv thiab khoom siv. Cov nqi no txwv rau cov txiaj ntsig tshiab hauv cheebtsheej thaum kuj tsim kev pab txhawb rau tus neeg siv kom hloov kho cov hluas siv tau. Qhov chaw tso tseg ntawm kev tso tseg thiab kev pab kho kev tsim kho tuaj yeem pab txhim kho kev siv hluas tshiab hauv kev lag luam.

FAQ

Yog vim li cas li hluas asynchronus yooj yim dua li lwm hom hluas

Qhov siv hluv tsis sib phim tuaj yam tsis tas xav kom muaj kev sib txuas nyob rau nruab nrab ntawm qhov chaw nres tseg thiab qhov chaw nres tseg hluv, tsis zoo li qhov siv hluv sib phim uas tswj xyuas kev sib raug nrog ntau dua. Qhov nres tseg ntawm rotor feem ntau yuav khoo siab rau hauv qab saum toj hluv nres tseg, tsim kev sib txawv uas pab tau rau kev tsim kws tshaj tawg. Qhov kev sau no yuav tsum xaiv tsis tau kev sau tshuaj meej meej lossis hluv tsis tu ncua, yog li tsim kho tsawg dua thiab tsis tas kho loj dua li lwm yam hluv.

Koj yuav mus kom paub qhov hluv tsis sib phim twg yog qhov tsim nyog rau kev siv

Kev xaiv cov khoom sib txawv yuav tsum tau soj ntsuam qhov kev sib raug zoo ntawm lub load, suav nrog kev xav tau ntawm torque khi kom ncig, kev xav tau ntawm torque nyob hauv kev ncig, thiab kev hlo li cas ntawm kev ncig hauv qhov kev ua haujlwm. Yuav tsum nrhiav kom paub qhov kev xav tau ntawm lub zog hauv qhov chaw sib txawv thiab xaiv ib lub motor uas muaj lub nuj nqi tsis tas dua, tab sis kuj tseem tshawb xyuas txog cov kev siv hauv qhov chaw sib txawv rau qee qhov sijhawm uas yuav tsum ncig ntau dhia. Cov kev txwv cai ntawm dej thiab av, lub sijhawm ua haujlwm, thiab cov kev xav tau ntawm kev muaj zog tuaj yeem txeeb xyuas lwm yam ntawm kev xaiv motor kom paub tias nws yuav ua haujlwm zoo tshaj plaws thiab nyob ntev rau hauv qhov kev siv tshwj xeeb no.

Puas yog cov motors asynchronous tuaj yeem ncig nrog kev hlo li cas ntawm kev ncig

Yea, cov roj teeb tsis sib xws tuaj yeem ua haujlwm nyob rau ntau tshaj li ib qhov khiav hauv kev sib raug xwm thiab muab cov cuab yeej kho. Qhov sib txig no muab kev sau caij zoo tagnrho uas tsim nyog rau kev ua haujlwm ntau tshaj li ib qhov khiav. Tus kheej khiav hauv kev hloov nrog lub tshuab kho, tiv thaiv kev tshwm sim ntawm kev hloov pauv, nrawm lossis kev nruab nrog tsis tas yuav siv cov cuab yeej kho.

Cov kev ua tib neeg tswv yim rau cov roj teeb tsis sib xws yog dab tsi

Kev txhim kho feem ntau muaj kev siv roj lubrication raws li kev cai tso los ntawm tus kws tsim khoom, kev saib xyuas kom sov tsis pub muaj dej ntsuag hauv qab, thiab kev test roj ib txhis kom pom kev nyiam xaim. Kev sau lub voj voog thiab kev soj hlwb pab pom cov teeb meem uas yuav tshwm sim ua ntej thaum twb poob. Feem ntau cov moter tsis siv asynchronous tsis xav tau ntau kev txhim kho kom compared to lwm hom motors, thiab kev hloov bearing yog qhov feem ntau tshaj plaws yuav tsum tau ua tom qab ib co xyoo nyob rau hauv kev siv thiab kev ncav cuag.

Daim Ntawv Qhia

- Cov Ntsiab Lus Ua Haujlwm Thaum Pib

- Kev tsim thiab Kev Sau Lub Ntu

- Kev ua haujlwm thiab kev nyab xeeb

- Kev Siv Hauv Tsev Tsim Khoom Thiab Qhov Siv

- Kev kho tshuab thiab kev daws teeb meem

- Kev Pab Pawg Tshiab Thiab Kev Tshwm Sim Ntawm Technology

-

FAQ

- Yog vim li cas li hluas asynchronus yooj yim dua li lwm hom hluas

- Koj yuav mus kom paub qhov hluv tsis sib phim twg yog qhov tsim nyog rau kev siv

- Puas yog cov motors asynchronous tuaj yeem ncig nrog kev hlo li cas ntawm kev ncig

- Cov kev ua tib neeg tswv yim rau cov roj teeb tsis sib xws yog dab tsi