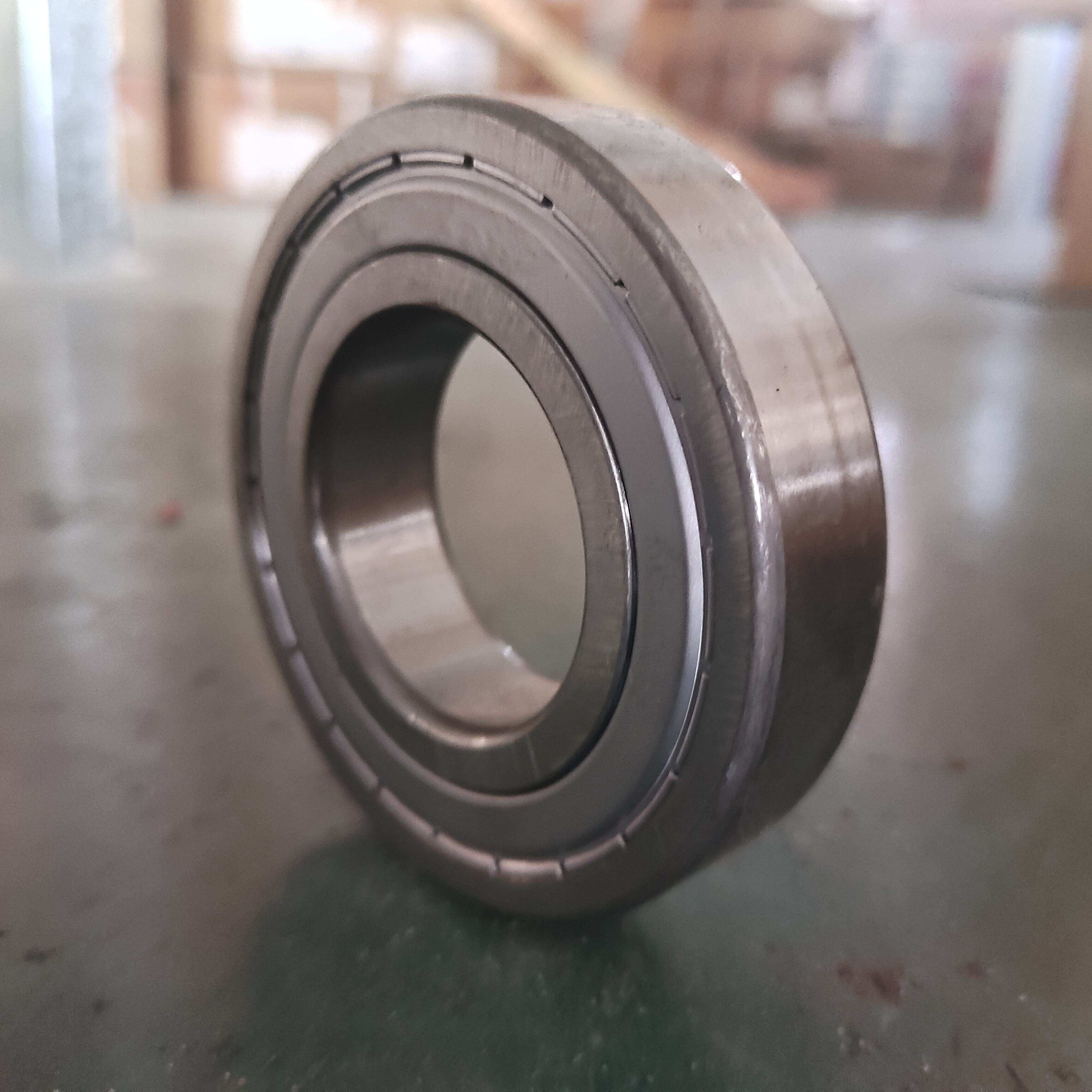

δημοφιλής κυλινδρικά άξονα

Οι δημοφιλείς τριβόμενοι ρουλεμάν αποτελούν ένα βασικό συστατικό των σύγχρονων μηχανικών συστημάτων, λειτουργώντας ως κρίσιμα στοιχεία που επιτρέπουν την ομαλή περιστροφική κίνηση ενώ υποστηρίζουν ακτινικά και αξονικά φορτία. Αυτές οι ακριβώς μηχανουργικές συσκευές αποτελούνται από εσωτερικούς και εξωτερικούς δακτυλίους, τριβόμενα στοιχεία όπως μπίλιες ή κυλίνδρους, καθώς και ένα θόλο ή συγκρατητήρα που διατηρεί την κατάλληλη απόσταση μεταξύ των τριβόμενων στοιχείων. Η κύρια λειτουργία των δημοφιλών τριβόμενων ρουλεμάν είναι η μείωση της τριβής μεταξύ κινούμενων εξαρτημάτων, με αποτέλεσμα την ελαχιστοποίηση της απώλειας ενέργειας και της φθοράς, ενώ μεγιστοποιείται η λειτουργική απόδοση. Τεχνολογικά, οι δημοφιλείς τριβόμενοι ρουλεμάν ενσωματώνουν προηγμένες γνώσεις στην επιστήμη των υλικών και την ακριβή παραγωγή για την επίτευξη βέλτιστων χαρακτηριστικών απόδοσης. Τα τριβόμενα στοιχεία κατασκευάζονται συνήθως από χάλυβα υψηλής ποιότητας που υφίσταται ειδικές θερμικές επεξεργασίες για τη βελτίωση της αντοχής και της ικανότητας φέρουσας ικανότητας. Οι σύγχρονοι δημοφιλείς τριβόμενοι ρουλεμάν διαθέτουν εξελιγμένα συστήματα λίπανσης, συμπεριλαμβανομένων σφραγισμένων σχεδιασμών που διατηρούν το λιπαντικό σε όλη τη διάρκεια ζωής λειτουργίας του ρουλεμάν, εξαλείφοντας την ανάγκη για συχνή συντήρηση. Οι εφαρμογές των δημοφιλών τριβόμενων ρουλεμάν καλύπτουν σχεδόν κάθε βιομηχανικό τομέα όπου υπάρχει περιστροφική κίνηση. Στις αυτοκινητοβιομηχανίες, αυτοί οι ρουλεμάν υποστηρίζουν τις συναρμολογήσεις των τροχών, τα κιβώτια ταχυτήτων και τα εξαρτήματα του κινητήρα. Η βιομηχανική μηχανική εξαρτάται από τους δημοφιλείς τριβόμενους ρουλεμάν για συστήματα μεταφοράς, αντλίες, κινητήρες και εξοπλισμό παραγωγής. Οι εφαρμογές στην αεροδιαστημική απαιτούν τα υψηλότερα πρότυπα απόδοσης, όπου οι δημοφιλείς τριβόμενοι ρουλεμάν λειτουργούν υπό ακραίες θερμοκρασίες και φορτία. Η κατασκευαστική βιομηχανία χρησιμοποιεί αυτούς τους ρουλεμάν σε βαρύ εξοπλισμό, γερανούς και εκσκαφείς. Ο αγροτικός εξοπλισμός, από τρακτέρ μέχρι μηχανήματα συγκομιδής, εξαρτάται από τους δημοφιλείς τριβόμενους ρουλεμάν για αξιόπιστη λειτουργία σε δύσκολες περιβαλλοντικές συνθήκες. Ιατρικές συσκευές και ακριβείς όργανα ενσωματώνουν επίσης μικροσκοπικές εκδόσεις δημοφιλών τριβόμενων ρουλεμάν για να εξασφαλίσουν ακριβή κίνηση και μακροχρόνια αξιοπιστία. Η ευελιξία και η προσαρμοστικότητα των δημοφιλών τριβόμενων ρουλεμάν τους καθιστούν αναπόσπαστους σε διάφορους τομείς, συμβάλλοντας στην ομαλή λειτουργία αμέτρητων μηχανικών συστημάτων παγκοσμίως.