Uitstekende Veelsydigheid en Toepassingsomvang

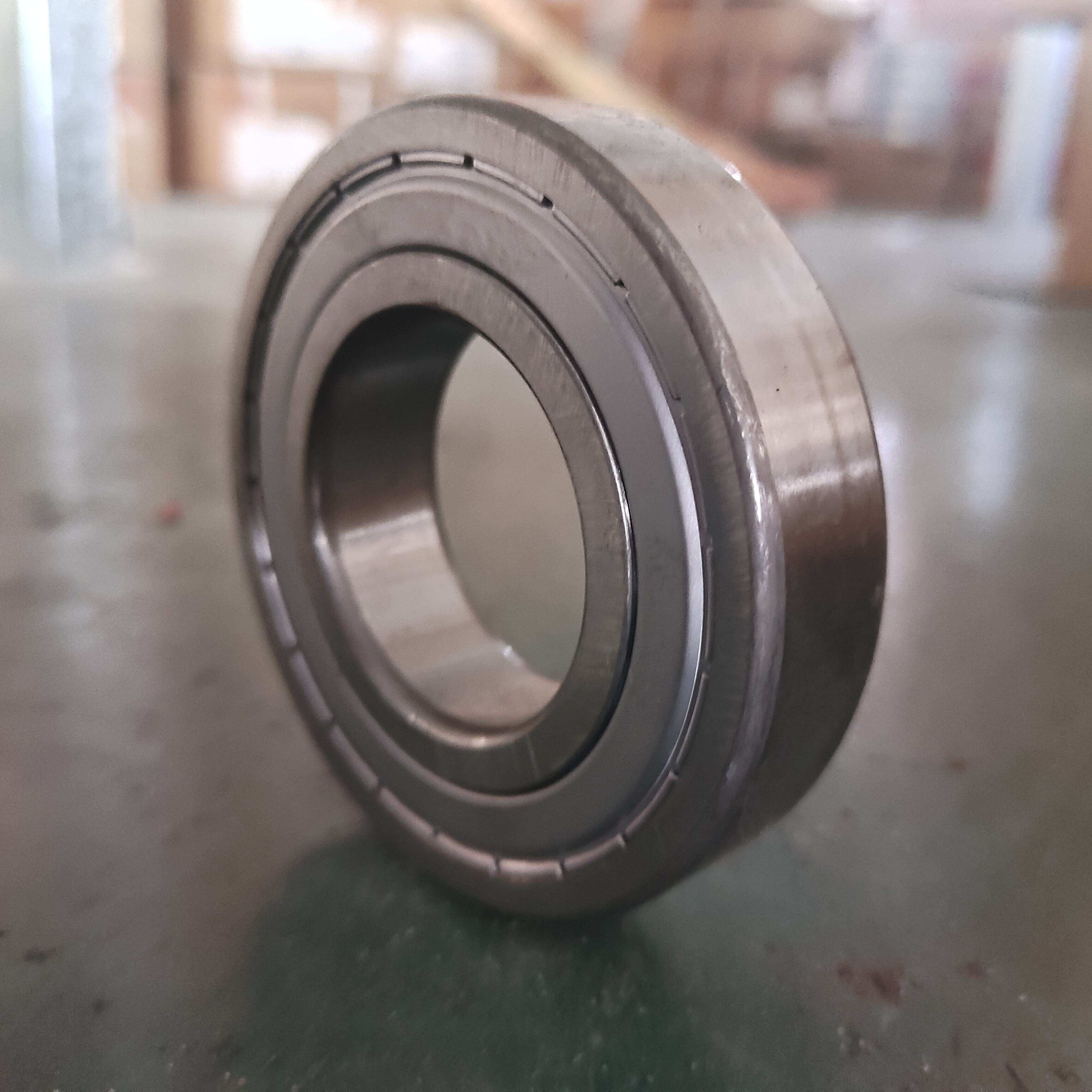

Gewilde rollelae toon opmerklike veerkragtigheid deur hul aanpasbaarheid aan 'n buitengewone verskeidenheid toepassings en bedryfsomstandighede. Hierdie aanpasbaarheid spruit uit die wye verskeidenheid laertipes wat beskikbaar is, insluitend diepgroef-kogellaers vir algemene toepassings, hoekkontak-laers vir gecombineerde belastings, silindriese rollelaers vir hoë radiale belastings, en taps-toe-loop rollelaers vir swaar toepassings. Elke tipe gewilde rollel word ontwerp om in spesifieke bedryfssituasies uit te blink, en bied optimale prestasiekenmerke vir uiteenlopende meganiese stelsels. Die grootteverskeidenheid van gewilde rollelaers strek van miniatuurpresisie-lae met boringdeursnitte so klein as een millimeter vir delikate instrumente tot reuse industriële laers wat meer as een meter in deursnee bereik vir swaar masjinerietoepassings. Hierdie omvattende beskikbaarheid van groottes verseker dat ingenieurs geskikte gewilde rollelaers kan vind vir feitlik enige toepassingsvereiste. Materiaalvariasies verhoog die veerkragtigheid verder, met gewilde rollelaers wat beskikbaar is in standaardstaal, roestvrye staal vir korrosiewe omgewings, keramiese materiale vir hoë-temperatuurtoepassings, en gespesialiseerde legerings vir ekstreme omstandighede. Smeeropsies voeg nog 'n dimensie van veerkragtigheid by, van oliesmering vir hoë-spoedtoepassings tot gespesialiseerde vetters wat saamgestel is vir spesifieke temperatuurbereik en bedryfsomstandighede. Gewilde rollelaers kan verskillende montagekonfigurasies hanteer, insluitend asmontage, behuismontage, en patroon-eenhede wat installasieprosedures vereenvoudig. Die beskikbaarheid van verskillende interne speelklasse laat ingenieurs toe om laerprestasie te optimaliseer vir spesifieke bedryfstemperature en aspassings. Spesiale oppervlakbehandelings en bedekkings brei die toepassingsgebied van gewilde rollelaers uit, en bied verbeterde korrosiewering, verminderde wrywing of beter slytasie-eienskappe. Aangepaste wysigings en gespesialiseerde ontwerpe verseker dat gewilde rollelaers unieke toepassingsvereistes kan bevredig, insluitend nie-standaardgroottes, spesiale materiale of aangepaste interne geometrieë. Hierdie uitstekende veerkragtigheid maak gewilde rollelaers die voorkeuroplossing vir ingenieurs oor alle nywerhede heen, van delikate mediese toestelle tot reuse industriële toerusting, en verseker optimale prestasie in elke spesifieke toepassing.