ειδικός άξονας

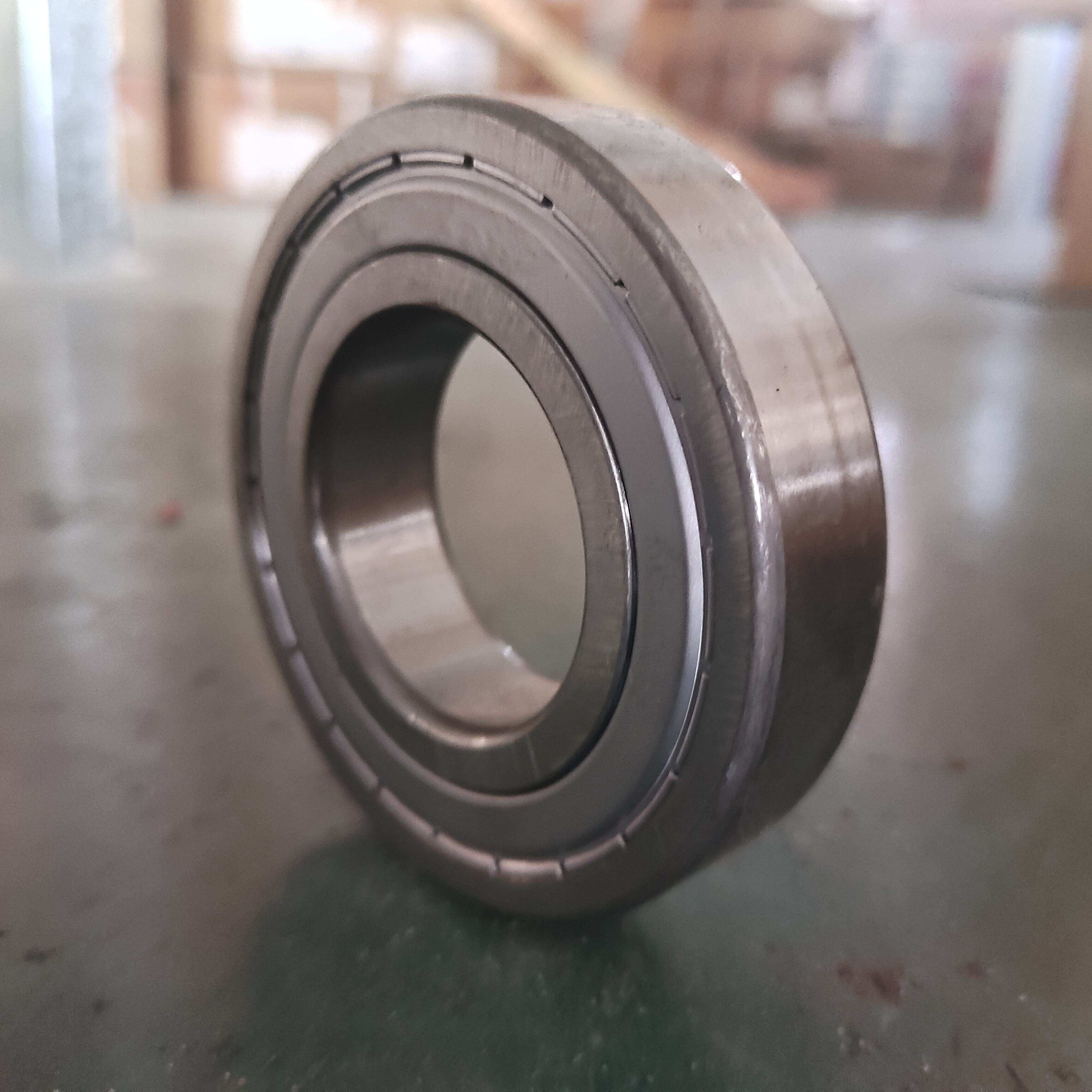

Ένα εξατομικευμένο ρουλεμάν αποτελεί μια ειδική μηχανική λύση που σχεδιάζεται για να καλύπτει συγκεκριμένες λειτουργικές απαιτήσεις, οι οποίες δεν μπορούν να εξυπηρετηθούν από τυποποιημένα ρουλεμάν. Σε αντίθεση με τα έτοιμα εξαρτήματα, οι λύσεις με εξατομικευμένα ρουλεμάν μηχανοποιούνται με μεγάλη προσοχή για να αντιμετωπίζουν μοναδικές προκλήσεις σε απαιτητικά βιομηχανικά περιβάλλοντα, παρέχοντας ανωτέρα απόδοση και αξιοπιστία. Αυτά τα ακριβώς κατασκευασμένα εξαρτήματα λειτουργούν ως κρίσιμα μηχανικά στοιχεία που διευκολύνουν την περιστροφική ή γραμμική κίνηση, υποστηρίζοντας φορτία και μειώνοντας την τριβή μεταξύ κινούμενων εξαρτημάτων. Η κύρια λειτουργία ενός εξατομικευμένου ρουλεμάν εκτείνεται πέρα από τη βασική υποστήριξη φορτίου, περιλαμβάνοντας ειδικές δυνατότητες όπως ανθεκτικότητα σε εξαιρετικά υψηλές θερμοκρασίες, συμβατότητα με χημικά, αυξημένη ικανότητα ταχύτητας και μοναδικές διαστασιακές προδιαγραφές. Τα τεχνολογικά χαρακτηριστικά των συστημάτων εξατομικευμένων ρουλεμάν περιλαμβάνουν προηγμένη επιλογή υλικών, ιδιόκτητα συστήματα λίπανσης, ειδικούς μηχανισμούς στεγανοποίησης και ακριβείς τεχνικές κατασκευής, οι οποίες εξασφαλίζουν άριστη απόδοση υπό συγκεκριμένες λειτουργικές συνθήκες. Η σύγχρονη ανάπτυξη εξατομικευμένων ρουλεμάν περιλαμβάνει καινοτόμες τεχνολογίες όπως κεραμικά υλικά, υβριδικές κατασκευές που συνδυάζουν στοιχεία από χάλυβα και κεραμικά, καθώς και ειδικές επικαλύψεις που αυξάνουν την αντοχή και την απόδοση. Οι εφαρμογές των εξατομικευμένων ρουλεμάν καλύπτουν διάφορους τομείς, όπως την αεροδιαστημική, την αυτοκινητοβιομηχανία, τον ιατρικό εξοπλισμό, τις ανανεώσιμες πηγές ενέργειας, τη βαριά μηχανική και ειδικές διεργασίες παραγωγής. Σε εφαρμογές αεροδιαστημικής, τα εξατομικευμένα εξαρτήματα ρουλεμάν πρέπει να αντέχουν εξαιρετικά υψηλές θερμοκρασίες, συνθήκες κενού και αυστηρά πρότυπα ασφαλείας, διατηρώντας ταυτόχρονα ακριβείς ανοχές. Η αυτοκινητοβιομηχανία βασίζεται στην τεχνολογία εξατομικευμένων ρουλεμάν για τους κινητήρες ηλεκτρικών οχημάτων (EV), τα συστήματα μετάδοσης και τις εφαρμογές υψηλής απόδοσης στους κινητήρες, όπου τα τυποποιημένα εξαρτήματα δεν μπορούν να καλύψουν τις απαιτητικές προδιαγραφές. Οι κατασκευαστές ιατρικού εξοπλισμού χρησιμοποιούν εξατομικευμένες λύσεις ρουλεμάν σε χειρουργικά εργαλεία, διαγνωστικό εξοπλισμό και συστήματα υποστήριξης ζωής, όπου η αξιοπιστία και η ακρίβεια είναι κρίσιμες. Οι τομείς των ανανεώσιμων πηγών ενέργειας, και ιδιαίτερα η παραγωγή ενέργειας από αιολικά πάρκα, εξαρτώνται από συστήματα εξατομικευμένων ρουλεμάν που μπορούν να αντέχουν τεράστια φορτία, μεταβλητές ταχύτητες και δυσμενείς περιβαλλοντικές συνθήκες για μεγάλα χρονικά διαστήματα. Οι εφαρμογές βαρέων βιομηχανικών μηχανημάτων απαιτούν εξατομικευμένες λύσεις ρουλεμάν ικανές να υποστηρίζουν τεράστια φορτία, διατηρώντας ταυτόχρονα τη λειτουργική αποτελεσματικότητα σε δύσκολα περιβάλλοντα, όπως χαλυβουργικά εργοστάσια, εξορύξεις και μηχανήματα κατασκευών.