Ekseptionel lastfordeling og strukturel ydeevne

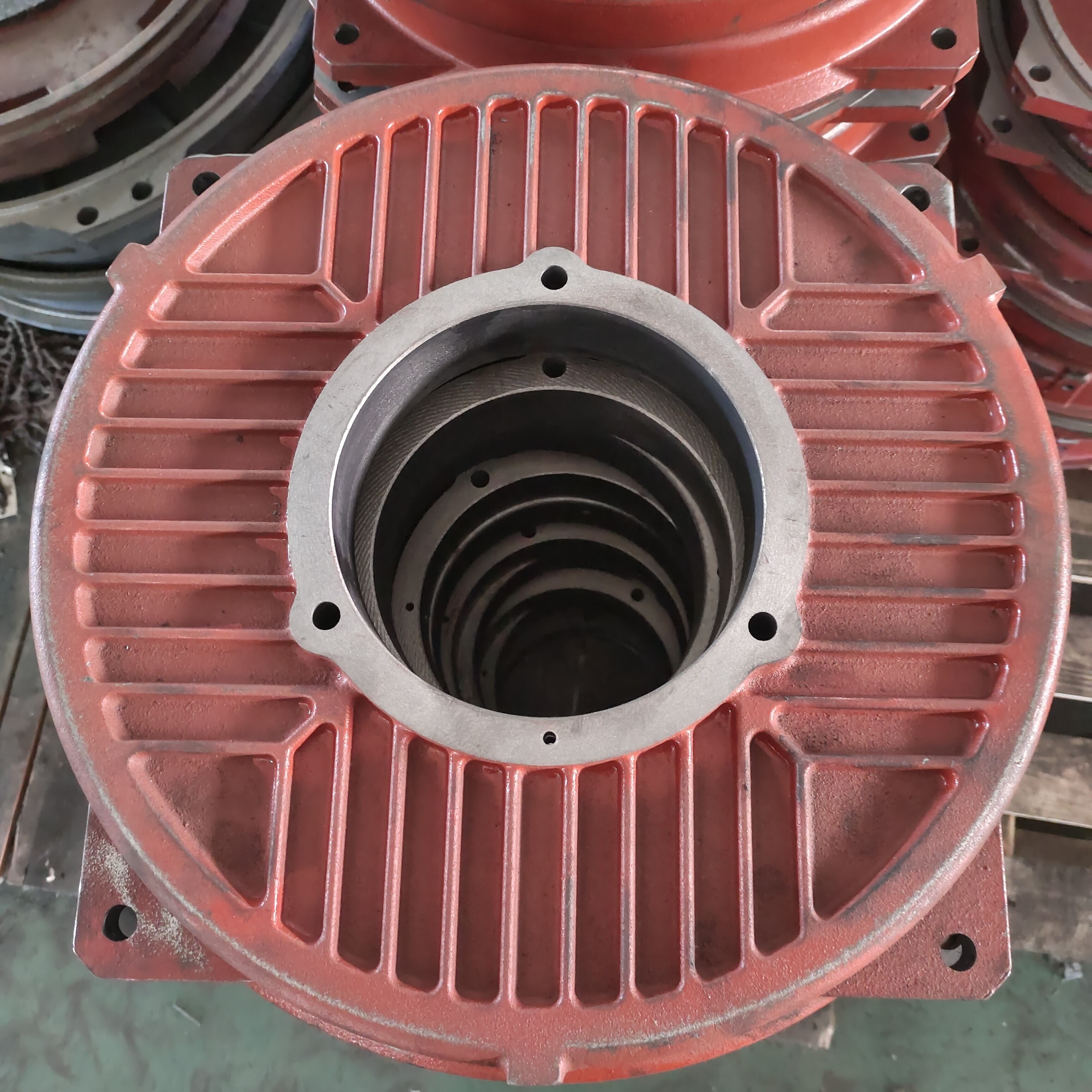

Den holdbare endeplade udmærker sig ved at fordele mekaniske belastninger jævnt over de tilknyttede enheder, hvilket giver en overlegen strukturel ydeevne, der forhindrer for tidlig komponentfejl og forlænger det samlede systemliv. Denne ekstraordinære belastningsfordeling er resultatet af avanceret ingeniøranalyse og computerstøttet designoptimering, der identificerer stresskoncentrationspunkter og omfordeler kræfter gennem strategisk placering af materiale og geometriske ændringer. Strukturen indeholder forstærkning, der kanaliserer belastninger langs optimale veje, samtidig med at vægt og materialeforbrug minimeres, hvilket skaber en effektiv løsning, der maksimerer styrke-til-vægt-forholdet. Finite elementanalyse under konstruktionsfasen sikrer, at belastningsniveauerne forbliver langt under materialgrænserne selv under topbelastningsforhold, hvilket giver betydelige sikkerhedsmargener, der kan imødekomme uventede driftskrav. Lastfordelingen forhindrer lokaliserede stresskoncentrationer, som ofte forårsager træthedsfejl i konventionelle konstruktioner, hvilket resulterer i dramatisk forbedret holdbarhed og pålidelighed. Flere belastningsveje indbygget i strukturen giver redundans, der opretholder strukturel integritet, selv hvis individuelle elementer oplever beskadigelse eller slitage under drift. Den geometriske konfiguration optimerer momentarmlængder og belastningsoverførselsvinkler for at minimere bøjningsspændinger og skærekræfter, der kan kompromittere langsigtet strukturel ydeevne. Der er taget hensyn til dynamisk belastning i konstruktionen for at sikre stabil ydeevne under vibrationer, stød og cykliske belastningsforhold, som almindeligvis forekommer i industrielle applikationer. Strukturel ydeevne gør det muligt for den holdbare endeplade at støtte tunge maskiner og højtrykssystemer uden at blive deformeret eller svigte, hvilket kan påvirke systemets justering og drift. Kunderne nyder godt af forbedret udstyrs pålidelighed, reduceret vibrationsoverførsel og forbedret driftsglatte, der bidrager til bedre produktkvalitet og proceskonsistens. Den ekstraordinære strukturelle ydeevne resulterer i lavere vedligeholdelsesomkostninger, færre uforudsete nedlukninger og en forbedret samlet udstyrseffektivitet, som direkte påvirker driftsrentabiliteten og konkurrencemæssig fordel på markedet.