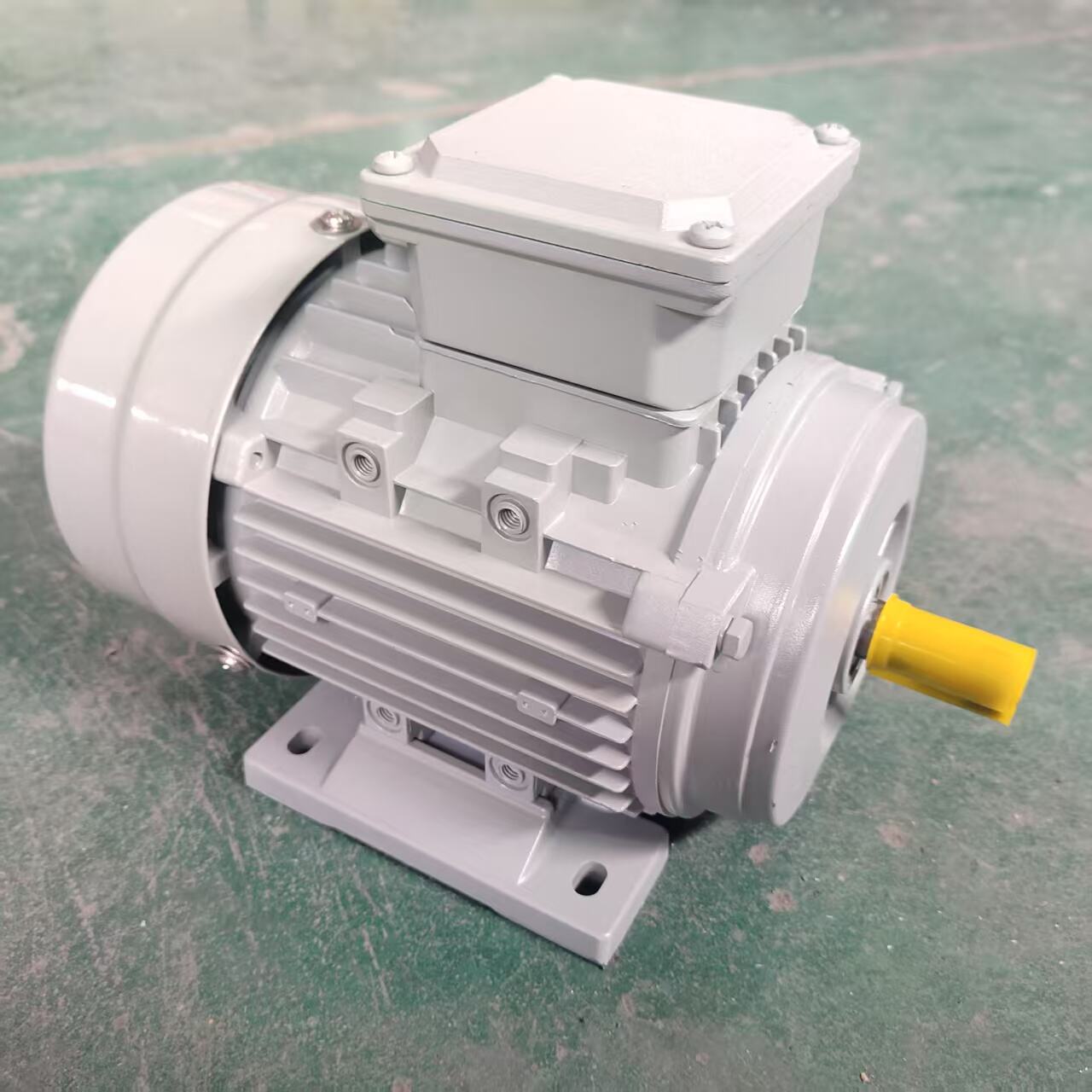

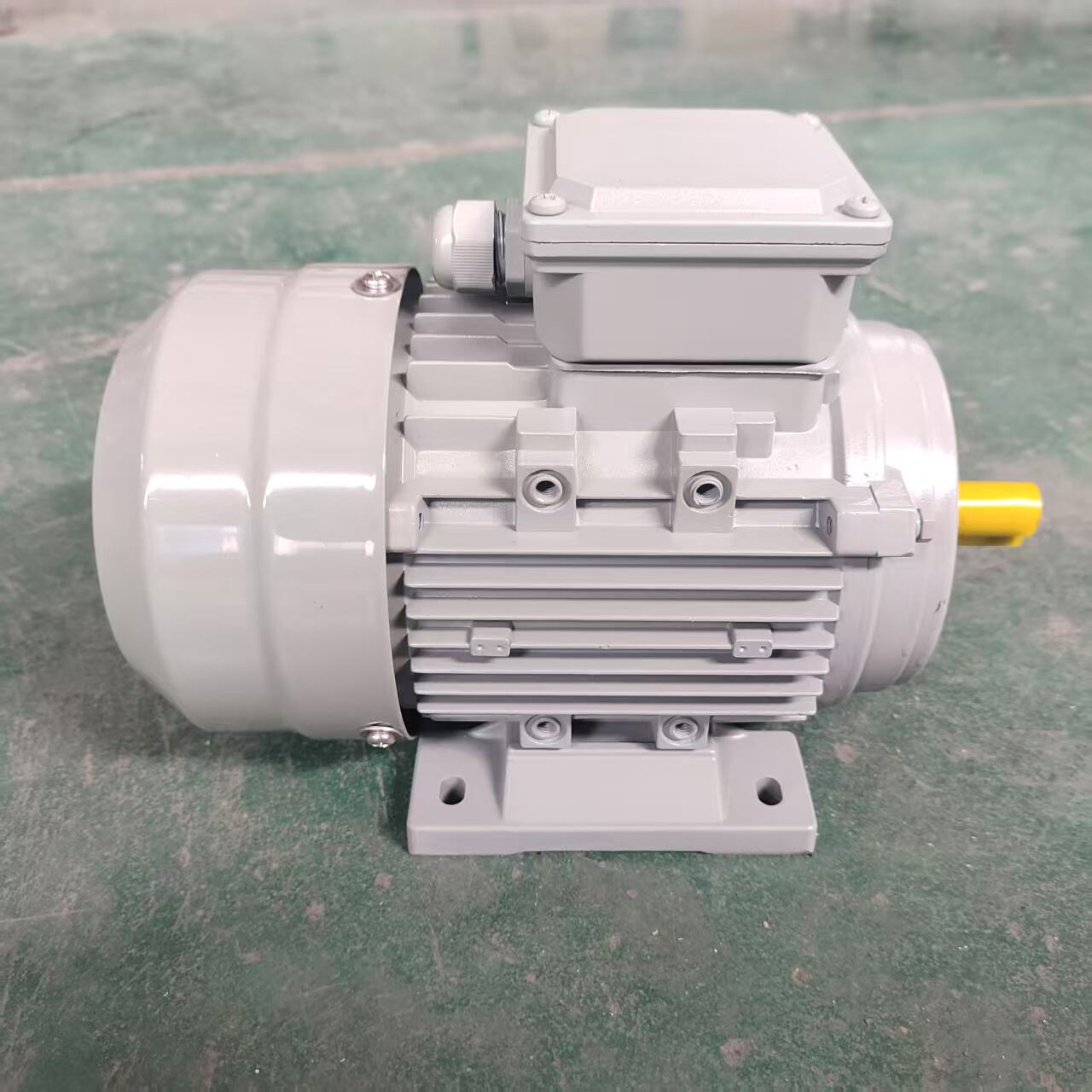

popular synchronous motor

The popular synchronous motor represents a sophisticated electrical machine that operates at a constant speed directly proportional to the frequency of the alternating current supply. This remarkable motor type achieves synchronization between its rotor speed and the rotating magnetic field produced by the stator windings, creating exceptional performance characteristics that distinguish it from other motor technologies. The popular synchronous motor incorporates advanced electromagnetic principles, utilizing either permanent magnets or electromagnets in its rotor construction to maintain precise speed control and deliver superior efficiency ratings. These motors feature a unique operational mechanism where the rotor rotates at exactly the same speed as the stator's magnetic field, eliminating slip and providing unwavering speed consistency regardless of load variations within normal operating parameters. The technological architecture of the popular synchronous motor includes sophisticated control systems that manage excitation currents, power factor correction capabilities, and advanced feedback mechanisms for optimal performance monitoring. Modern variants incorporate variable frequency drives, digital control interfaces, and smart diagnostic systems that enhance reliability and operational intelligence. The popular synchronous motor finds extensive applications across industrial sectors including manufacturing automation, precision machining, conveyor systems, compressors, pumps, and renewable energy generation facilities. In power generation applications, these motors serve as generators in hydroelectric plants, wind turbines, and thermal power stations, demonstrating their versatility and engineering excellence. The motor's ability to operate at leading, lagging, or unity power factors makes it particularly valuable in electrical grid management and power quality improvement initiatives. Manufacturing industries leverage the popular synchronous motor for applications requiring precise speed control, such as textile machinery, paper mills, steel rolling mills, and chemical processing equipment where consistent operational parameters directly impact product quality and production efficiency.