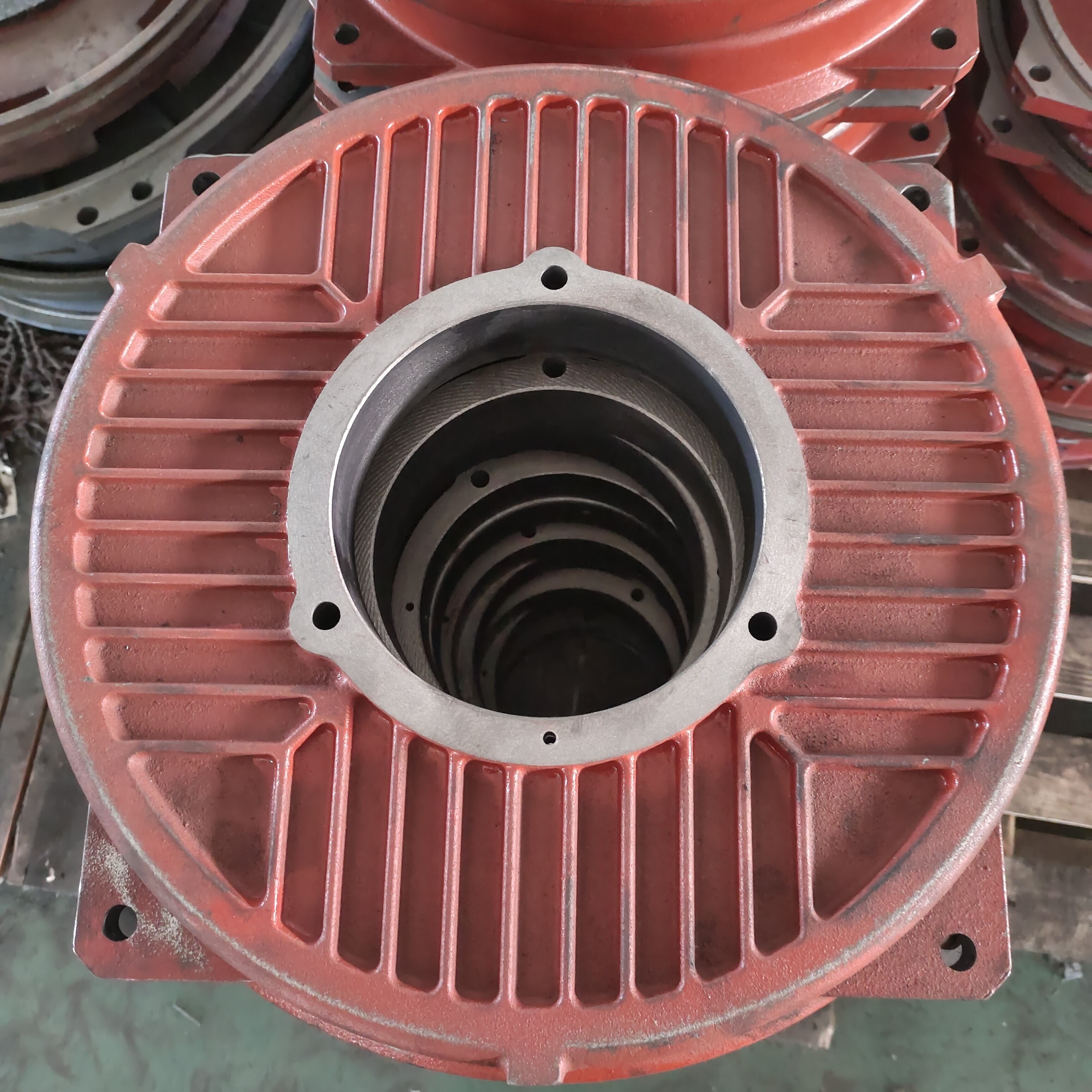

geavanceerde eindplaat

De geavanceerde eindplaat vormt een revolutionaire doorbraak in het ontwerp van industriële componenten en fungeert als een cruciaal koppelingselement dat verschillende mechanische systemen verbindt met ongekende precisie en betrouwbaarheid. Deze geavanceerde component fungeert als het eindpunt in diverse mechanische constructies, waarbij de structurele integriteit wordt gewaarborgd terwijl tegelijkertijd optimale prestatienormen worden gehandhaafd over uiteenlopende industriële toepassingen heen. De geavanceerde eindplaat integreert modern materiaalonderzoek en ingenieursprincipes om een superieure functionaliteit te bieden in vergelijking met traditionele alternatieven. Haar primaire functie bestaat uit het creëren van veilige verbindingen tussen verschillende systeemcomponenten, terwijl mechanische belastingen gelijkmatig worden verdeeld over de gehele constructie. De technologische kenmerken van de geavanceerde eindplaat omvatten oppervlakken die met hoge precisie zijn bewerkt, zodat perfecte uitlijning en minimale tolerantie-afwijkingen worden gegarandeerd. Deze componenten maken gebruik van geavanceerde metallurgietechnieken, met name hoogwaardige legeringen die bestand zijn tegen corrosie, vermoeiing en extreme temperatuurschommelingen. Het productieproces maakt gebruik van computergestuurde bewerkingscentra die micronnauwkeurigheid realiseren, wat consistentie in kwaliteit garandeert bij elke productierun. Oppervlaktebehandelingen die op de geavanceerde eindplaat worden toegepast, verbeteren de duurzaamheid en prestatiekenmerken aanzienlijk. Toepassingen van de geavanceerde eindplaat strekken zich uit over meerdere sectoren, waaronder lucht- en ruimtevaart, automobielindustrie, productie, energieopwekking en zware machines. In de lucht- en ruimtevaart moeten deze componenten voldoen aan strenge veiligheidseisen, terwijl zij tegelijkertijd lichtgewicht moeten blijven. Automobiele fabrikanten vertrouwen op geavanceerde eindplaten voor motoren, transmissiesystemen en ophangingscomponenten, waarbij betrouwbaarheid direct invloed heeft op voertuigprestaties en veiligheid. Productiebedrijven gebruiken deze componenten in productiemachines, transportbanden en geautomatiseerde systemen, waaruitval aanzienlijke kosten kan veroorzaken. De energiesector is afhankelijk van geavanceerde eindplaten voor turbineconstructies, generatorsystemen en pijpleidingaansluitingen, waar een defect catastrofale gevolgen kan hebben. Elke toepassing stelt specifieke prestatie-eisen, die de geavanceerde eindplaat consequent vervult dankzij zijn superieure ontwerp- en fabricagekwaliteit.