Ավելացված կարողանք և պատմական իրավիճակի հաստատություն

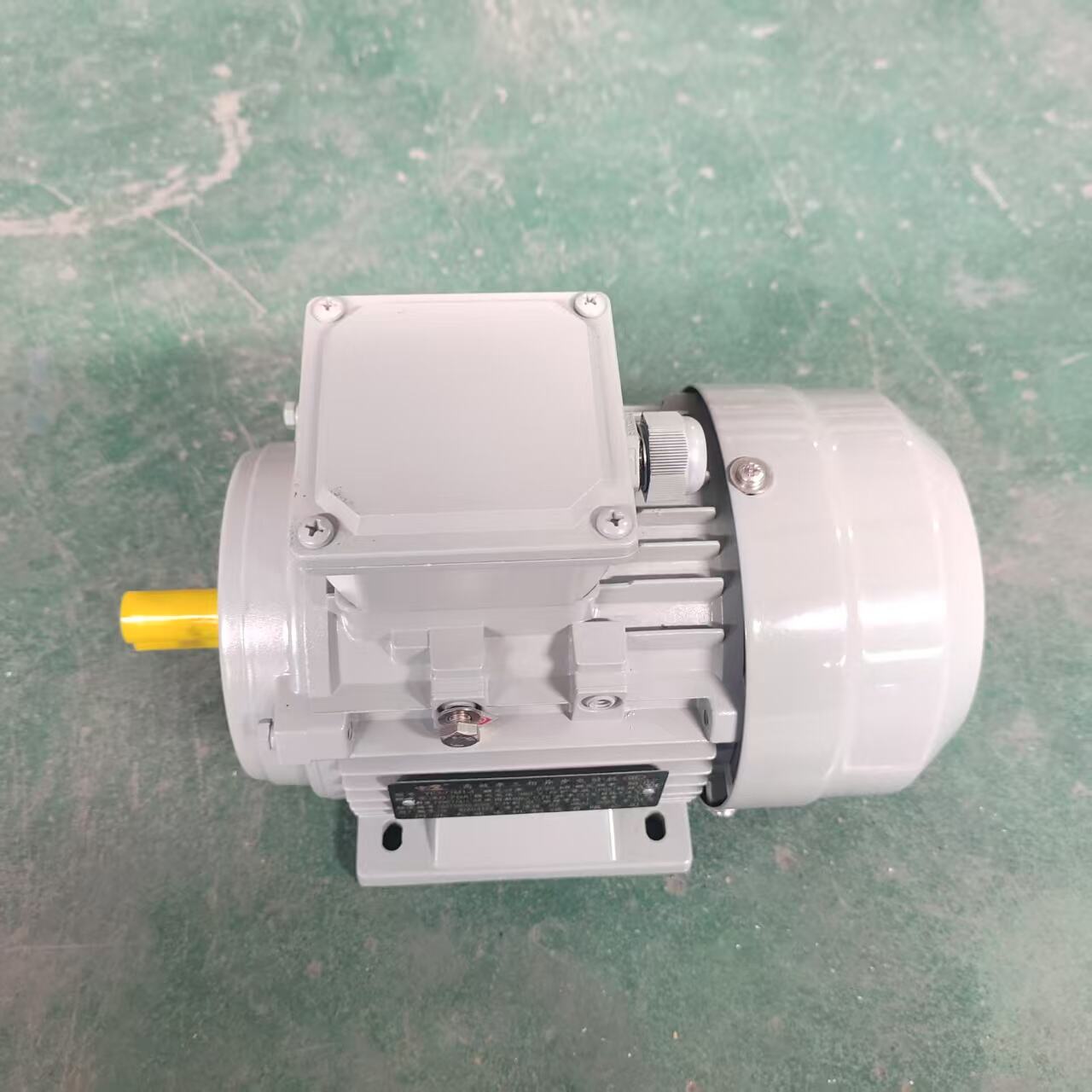

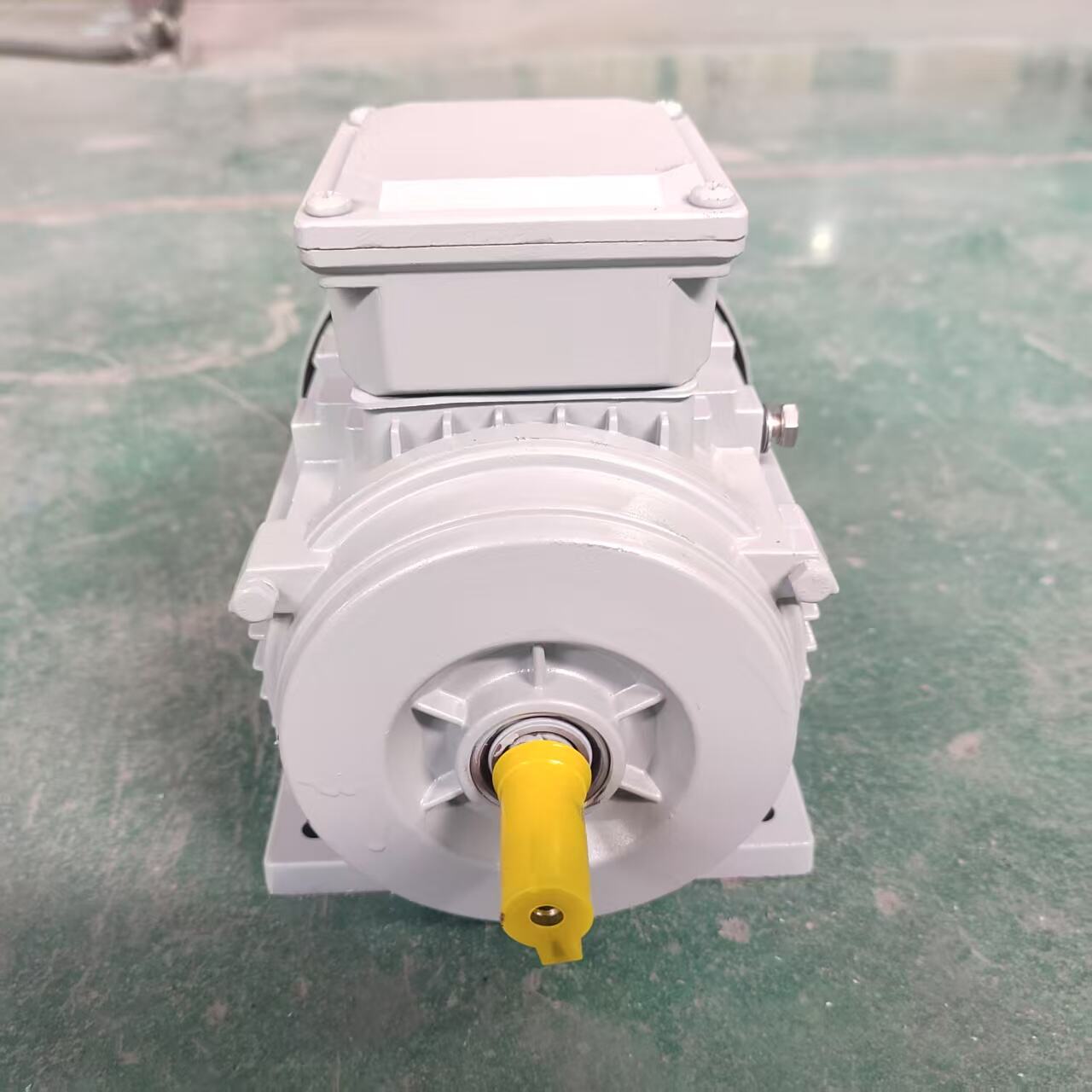

Վերջին նախագծված սինխրոն շարժիչը ցուցադրում է բացառիկ ամրություն առաջադեմ նյութերի ինժեներիայի եւ պաշտպանական նախագծման առանձնահատկությունների շնորհիվ, որոնք ապահովում են հուսալի աշխատանքը դժվար արդյունաբերական միջավայրերում: Մոտորի տնակը օգտագործում է բարձրորակ ալյումինե ալյումինե ալյումինե եւ հատուկ ծածկույթներ, որոնք դիմադրում են կոռոզիային, քիմիական նյութերի ազդեցությանը եւ մեխանիկական վնասներին, պահպանելով կառուցվածքային ամբողջականությունը երկարատեւ գործառնական ժամանակահատ Մատչելի է, որ մոդելները կարող են խանգարել մոդելների շարժիչների աշխատանքին։ Վերջին նախագծված սինխրոն շարժիչի լեյինգների հավաքածուները ներառում են բարձրակարգ նյութեր եւ առաջադեմ յուղային համակարգեր, որոնք զգալիորեն երկարացնում են գործառնական կյանքը արդյունաբերական ստանդարտներից դուրս: Մոտորի ջերմաստիճանի կառավարման համակարգերը կանխում են ջերմային վնասը ջերմության արդյունավետ հեռացման եւ ավտոմատ պաշտպանության արձանագրությունների միջոցով, որոնք արձագանքում են չափազանց բարձր ջերմաստիճանի պայմաններին: Ստատորային կաշառքները օգտագործում են բարձր ջերմաստիճանի մեկուսացման նյութեր, որոնք պահպանում են էլեկտրական հատկությունները նույնիսկ ծայրահեղ ջերմային լարվածության պայմաններում, ապահովելով հետեւողական կատարում եւ կանխելով մեկուսացման խափանումը, որը հանգեցնում է թանկ վնասների: Վիբրացիայի խոնավեցման տեխնոլոգիաները, որոնք ինտեգրված են վերջին նախագծման սինխրոն շարժիչի մեջ, նվազեցնում են բոլոր բաղադրիչների վրա մեխանիկական լարվածությունը, երկարացնում կյանքի տեւողությունը եւ ժամանակի ընթացքում պահպանում ճշգրտության կատարումը: Մոտորի կառուցվածքը ներառում է ցնցումների դիմացկուն հատկություններ, որոնք պաշտպանում են տրանսպորտի, տեղադրման եւ արդյունաբերական միջավայրերում նորմալ գործարկման ժամանակ վնասվածքների դեմ: Շրջակա միջավայրի պաշտպանության գնահատականները ցույց են տալիս շարժիչի ունակությունը արդյունավետորեն աշխատել արտաքին տեղակայանքներում, լվացքի տարածքներում եւ այլ պահանջարկային պայմաններում, որտեղ սովորական շարժիչները պահանջում են լրացուցիչ պաշտպանական կահույքներ: Արտադրության ընթացքում որակի վերահսկման գործընթացները ապահովում են, որ յուրաքանչյուր վերջին նախագծված սինխրոն շարժիչը համապատասխանում է ամուր ամրության չափանիշներին համապարփակ փորձարկման արձանագրությունների միջոցով, որոնք նմանեցնում են տարիների աշխատանքային լարվածությունը: Մոդուլային բաղադրիչների նախագծումը հեշտացնում է պահպանման ընթացակարգերը ՝ նվազագույնի հասցնելով փոխարինման ծախսերը, երբ սպասարկումը անհրաժեշտ է դառնում երկարատեւ գործառնական ժամանակահատվածներից հետո: Էլեկտրամագնիսական պաշտպանումը պաշտպանում է զգայուն կառավարման էլեկտրոնիկան արտաքին խանգարումների դեմ, իսկ արգելում է շարժիչին ազդել մոտակա էլեկտրոնային սարքավորումների վրա: Հզոր կառուցվածքի փիլիսոփայությունը ապահովում է, որ վերջին նախագծված սինխրոն շարժիչը շարունակում է հետեւողական կատարում ունենալ նույնիսկ հաճախակի մեկնարկների, կանգների եւ բեռի փոփոխությունների ենթարկվելիս, որոնք կստիպեն սովորական շարժիչների նախագծերը: Գվարդիայի ապահովումը արտացոլում է արտադրողի վստահությունը շարժիչի ամրության նկատմամբ, օգտագործողներին տրամադրելով ֆինանսական պաշտպանություն եւ մտքի խաղաղություն իրենց սարքավորումների ներդրումների համար: