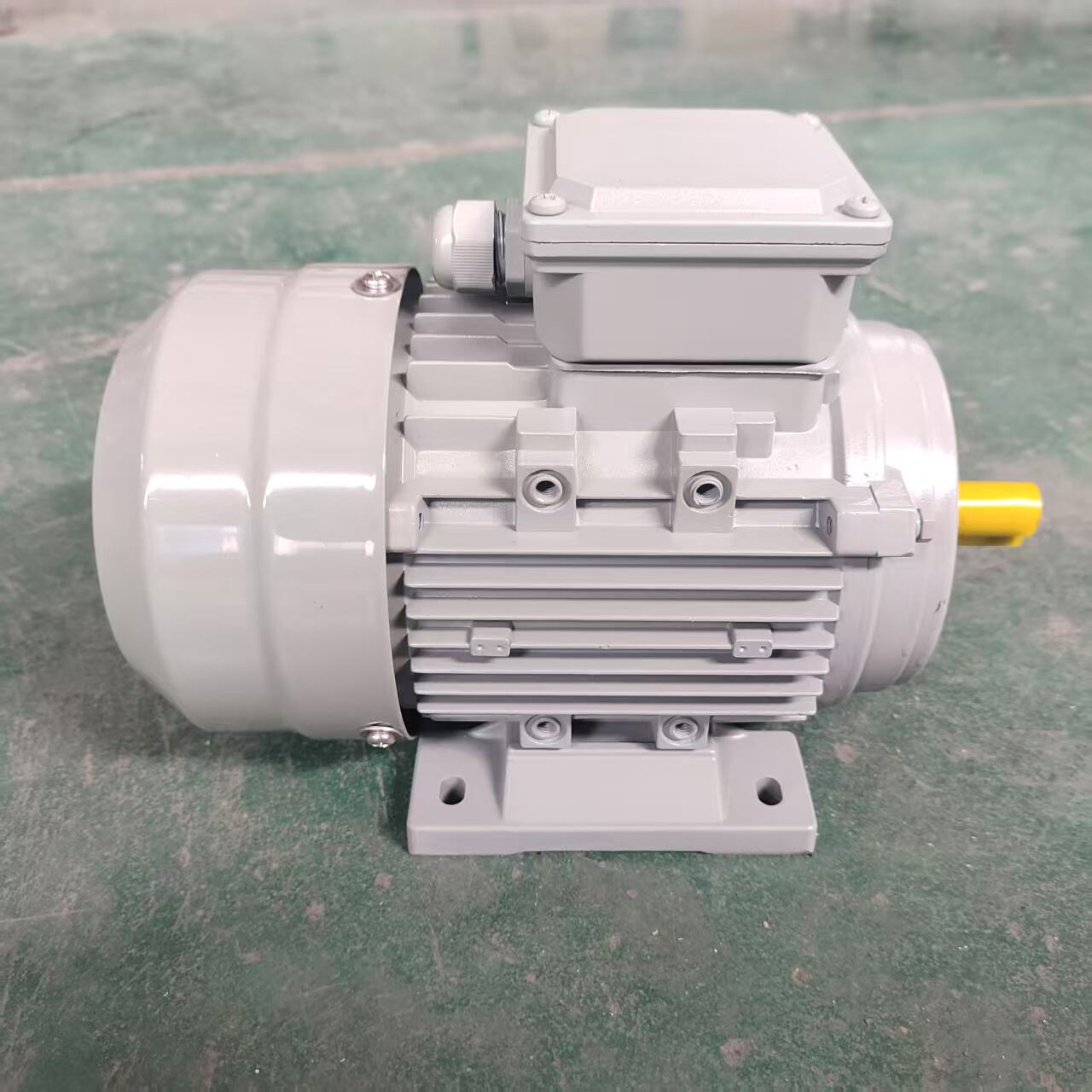

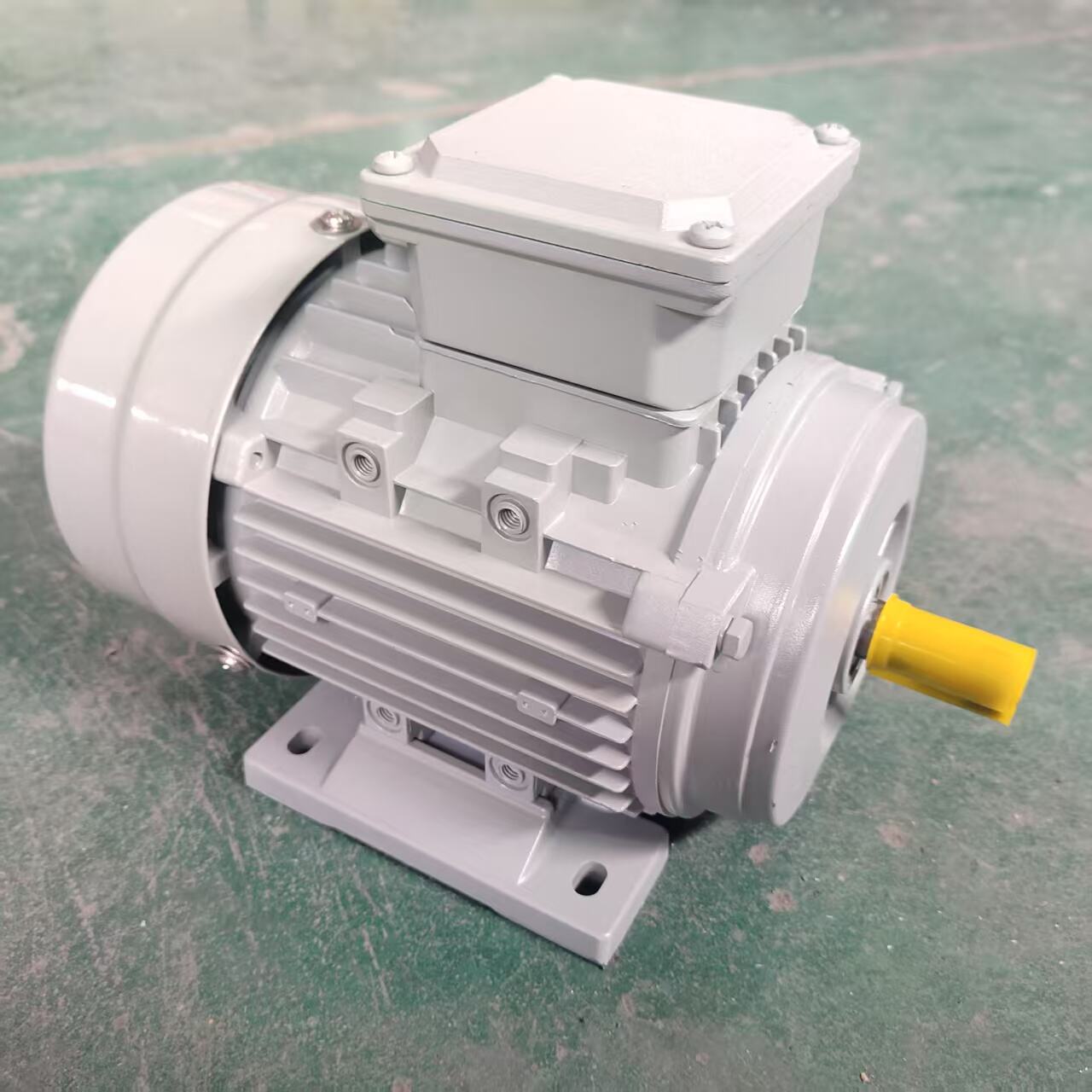

Գերազանց տևողականություն և ցածր սպասարկման պահանջներ

Հիանալի սինխրոն շարժիչը ներառում է առաջադեմ ինժեներական եւ բարձրակարգ նյութեր, որոնք ապահովում են բացառիկ ամրություն եւ նվազագույնի հասցնում պահպանման պահանջները, ապահովելով երկարաժամկետ արժեք արդյունաբերական ներդրումների համար: Հզոր կառուցվածքը սկսվում է բարձրորակ մշտական մագնիսներով, որոնք պահպանում են իրենց մագնիսական հատկությունները տասնամյակների ընթացքում, վերացնելով այլ շարժիչ տեխնոլոգիաների սովորական աստիճանական կատարողականի վատթարացումը: Հազվագյուտ հողերի մշտական մագնիսները դիմադրում են ջերմաստիճանի տատանումներին, մեխանիկական ցնցումներին եւ էլեկտրական անցումայիններին, ապահովելով մոնտաժի մշտական կատարումը ամբողջ կյանքի ընթացքում: Հիանալի սինխրոն շարժիչի լեռնաշղթաների համակարգերը օգտագործում են ճշգրտությամբ նախագծված բաղադրիչներ, որոնք ունեն առաջադեմ յուղային համակարգեր, որոնք երկարացնում են սպասարկման միջակայքները եւ նվազեցնում պահպանման ծախսերը: Շատ սարքավորումներ անընդհատ աշխատում են 3-5 տարի ժամանակահատվածում պլանավորված պահպանման ընթացակարգերի միջեւ, համեմատած ավանդական շարժիչների հետ, որոնք պահանջում են եռամսյակային կամ կիսամսյա սպասարկում: Մշտական մագնիսների տարբերակներում սահող օղակների, խոզանակների եւ մաշկվածության վրա հիմնված այլ բաղադրիչների բացակայությունը վերացնում է ընդհանուր ձախողման կետերը եւ նվազեցնում է սպառման մնացորդների առաջացումը, որոնք կարող են աղտոտել զգայուն արտադրական միջավայր Ջերմային կառավարման համակարգերը, որոնք ներառում են գերազանց սինխրոն շարժիչի նախագիծը, կանխում են գերծերմացման պայմանները, որոնք սովորաբար առաջացնում են սովորական շարժիչների վաղաժամ անսարքություն: Մոտորների համար նախատեսված բարձր ջերմաստիճանի մեկուսացման նյութերը թույլ են տալիս հուսալիորեն աշխատել պահանջկոտ միջավայրերում՝ պահպանելով կատարողականի բնութագրերը: Մոտորի տնակը օգտագործում է կոռոզիային դիմացկուն նյութեր եւ պաշտպանական ծածկույթներ, որոնք դիմադրում են արդյունաբերական վայրերում սովորաբար հանդիպող քիմիական նյութերի, խոնավության եւ կեղտոտ մասնիկների ազդեցությանը: Արտադրության ընթացքում որակի վերահսկման ընթացակարգերը ապահովում են, որ յուրաքանչյուր գերազանց սինխրոն շարժիչը մինչեւ առաքումը համապատասխանում է հստակ հուսալիության չափանիշներին, նվազեցնում է նորածինների մահացության մակարդակը եւ երաշխիքային պահանջները: Ժամանակակից տարբերակներում ինտեգրված կանխատեսելի պահպանման հնարավորությունները հնարավորություն են տալիս վերահսկել վիճակը, որը հայտնաբերում է հնարավոր խնդիրները, նախքան դրանք խափանումներ առաջացնելուը, ինչը թույլ է տալիս պլանավորված պահպանություն իրականացնել պլանավորված անջատման ժամանակ, այլ ոչ թե արտակարգ վերանորոգումներ: Մոդուլային դիզայնի փիլիսոփայությունը հնարավորություն է տալիս փոխել բաղադրիչները առանց շարժիչի ամբողջական հեռացման, նվազագույնի հասցնելով պահպանման տեւողությունը եւ հետ կապված արտադրական կորուստները: Ամբողջական փաստաթղթերը եւ լայնորեն հասանելի պահեստամասերի աջակցությունը ապահովում են, որ սպասարկման անձնակազմը կարող է արագ լուծել ցանկացած սպասարկման պահանջ, հետագայում նվազեցնել անջատման ժամանակի ծախսերը եւ պահպանել արտադրության ժամանակացույցները: