Industri-grads holdbarhed og pålidelighed

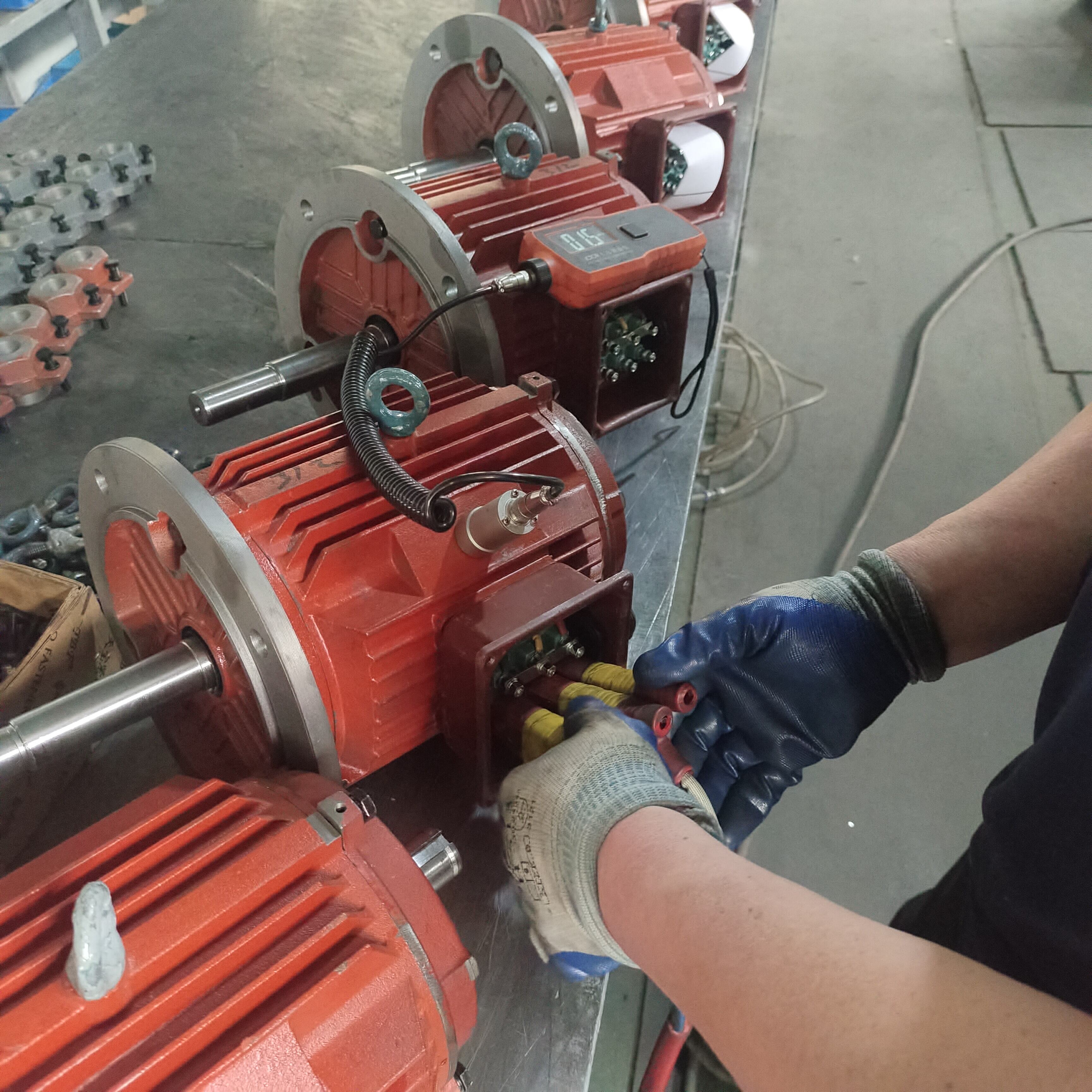

Kinesiske omdrejningshastighedssystemer demonstrerer enestående industriel holdbarhed og pålidelighed, designet til at modstå de mest krævende driftsmiljøer. Den robuste konstruktion anvender materialer af høj kvalitet og avancerede fremstillingsmetoder, der sikrer konsekvent ydelse over langvarige driftsperioder. Komponenterne gennemgår omfattende testprocedurer, herunder temperaturcykling, vibrationsmodstand, elektromagnetisk kompatibilitet og accelererede aldringstests, som bekræfter ydeevnen under ekstreme forhold. Kapslingsdesignene opfylder internationale beskyttelsesstandarder, herunder IP65/IP67-klassificeringer, og giver fuld beskyttelse mod støv, fugt og kemiske forureninger, som ofte findes i industrielle miljøer. Avancerede kølesystemer opretholder optimale driftstemperaturer, selv ved høje omgivelsestemperaturer, hvilket forhindrer termisk nedbrydning og forlænger levetiden for komponenter. De elektriske komponenter har specifikationer til industriel brug med udvidede temperaturområder, forbedret overspændingsbeskyttelse og øget immunfølelighed over for elektromagnetiske interferenser. Disse specifikationer sikrer pålidelig drift i miljøer med betydelig elektrisk støj, strømkvalitetsproblemer og elektromagnetisk interferens. De mekaniske komponenter anvender præcisionslejer, hårdnede aksler og korrosionsbestandige materialer, der opretholder nøjagtighed og jævn drift gennem hele deres levetid. Kvalitetssikringsprocedurer omfatter omfattende fabrikstest af hvert system før afsendelse, således at leverede produkter opfylder strenge ydelsesspecifikationer. Pålidelighedsfunktionerne omfatter redundante kritiske komponenter, som giver backup-funktionalitet ved fejl i primære komponenter, og derved sikrer kontinuerlig drift og minimerer risikoen for nedetid. Avancerede diagnostiske funktioner overvåger kontinuert komponenternes tilstand og giver tidlige advarsler for forebyggende vedligeholdelsesforanstaltninger. Systemerne inkluderer omfattende fejlregistrerings- og isoleringsmekanismer, der hurtigt identificerer og isolerer problemer, for at forhindre kaskadebrud og reducere reparationers kompleksitet. Modulært designarkitektur muliggør hurtig udskiftning af komponenter og systemomkonfiguration uden omfattende nedetid eller specialværktøjer. Holdbarheden rækker også til softwarekomponenter gennem robust fejlhåndtering, automatiske genoprettelsesmekanismer og omfattende databeskyttelsesfunktioner, der beskytter mod data tab og systemkorruption. Miljømæssig tilpasning tillader drift i ekstreme temperaturer fra -40°C til +70°C, fugtighedsniveauer op til 95 % og højder op til 3000 meter. Pålidelighedshistorikken inkluderer dokumenteret middel tid mellem fejl på over 50.000 timer under normale driftsforhold, hvilket demonstrerer enestående langsigtede pålidelighed for kritiske industrielle applikationer.