Usus vari et admodum integrabiles

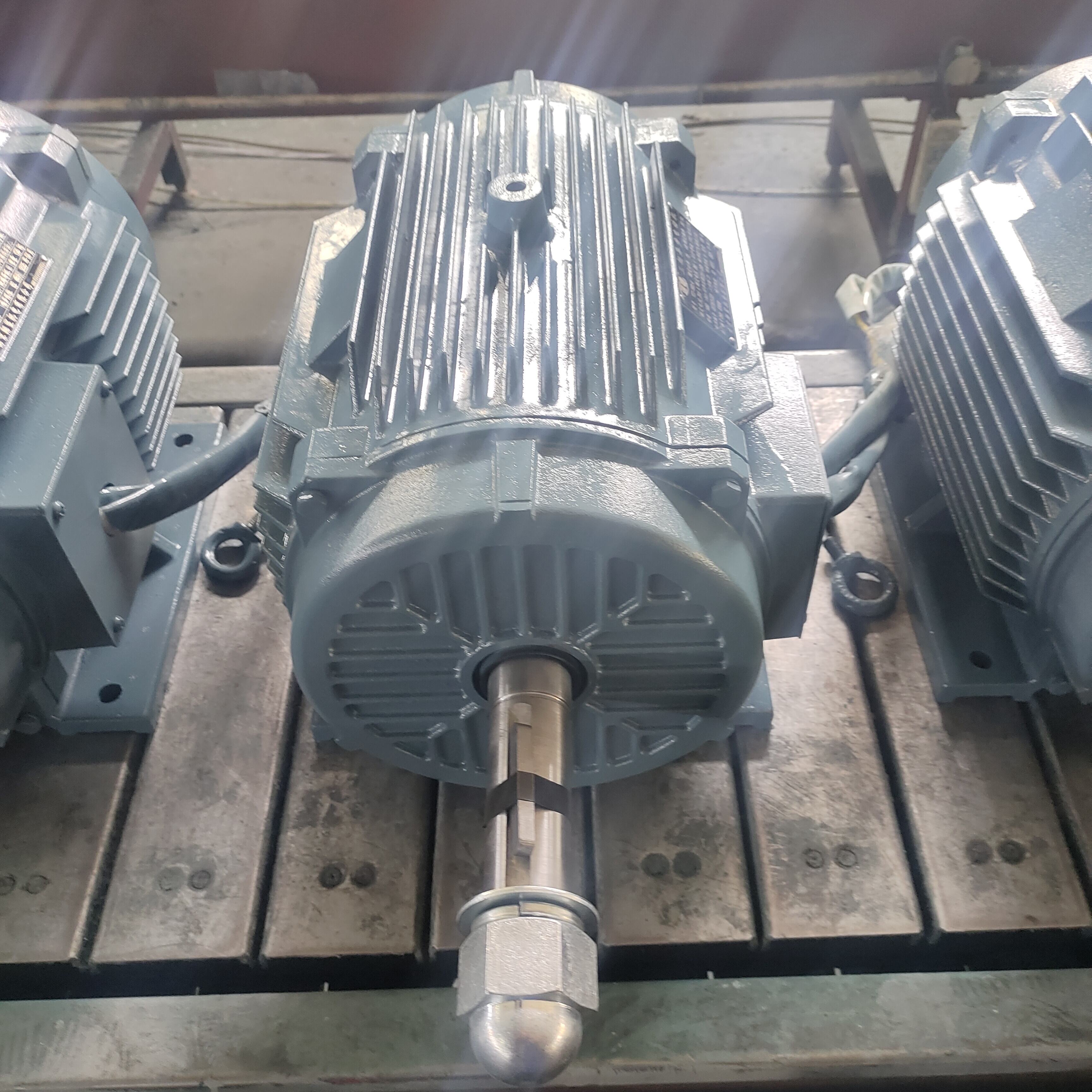

Motor asynchronus qualitatis notabilis versatilitas demonstrat, quae eum ad latissimam applicationum varietatem in multis industriae ramis et operationalibus necessitatibus idoneum reddit. Hi motores systematibus iam existentibus necnon novis installationibus pari passu integrantur, praebendo flexibilitatem quae diversis clientium necessitatibus et specificatis conditionibus satisfacit. Motor asynchronus qualitatis variis tensionis gradibus effice valde operatur, inter quos 208V, 230V, 460V, et altiores industriales tensiones, diversisque electricis infrastructurae conditionibus absque mutatione accommodat. Frequentialis compatibilitas a standardibus 50Hz et 60Hz alimentationibus usque ad frequentias variabiles extenditur, cum idoneis impulsoribus sistemonibus iuncta. Potentiae classificationes a fractionibus caballorum validorum, quae parvis instrumentis apta sunt, usque ad multi-megavattos motores, qui magnam machinariam industrialem movent, patet. Hi motores in applicationibus constantis velocitatis, ut ventilo et pompis, necnon in applicationibus velocitatis variabilis, sicut systemata convectorea et machinae processuales, excellunt. Configurationes montandi includunt montationem pedali, montationem per laminam (flange), et optiones montationis speciales quae ad peculiares conditiones installationis et spatii angustias adaptantur. Motor asynchronus qualitatis in duris condicionibus fidelem operationem praebet, cum temperie ab -20°C usque ad +60°C et altitudinis facultatibus usque ad 1000 metra supra mare. Optiones clausurae includunt apertas contra stillas munitas, complete inclusas et ventilator-rigidas, necnon explosioni-resistentes formas, quae peculiarem ambientem et tutelam conditiones implent. Industriae, inter quas manufactura, metallurgia, petrolei et gasi, tractatio aquarum, HVAC, et sectores energiarum renouabilium, his motoribus in operationibus essentialibus confidunt. Applicationes agriculturales proficiunt ex facultate motorum in tenebris et humidis condicionibus operandi, dum tamen fi duciam constantem servent. Applicationes maritimae et offshore versiones speciales utuntur, quae protectionem contra corrosionem et resistentiam vibrationi augentem habent. Hi motores facile cum modernis regulandis systematis, inter quos programmabiles logicae regulatores (PLC), homini-machinae interface, et industriales nuntiationis rete, integrantur. Compatibilitas cum variabilis frequentiae impellentibus (VFD) praecisam velocitatis regulationem, mollem initium, et optimisationem energiae permittit. Installationis procedurae simplices manent, cum electricis connectionibus standard et mechanicis montandi systematis, quae tempus et expensas commissionis minuunt.