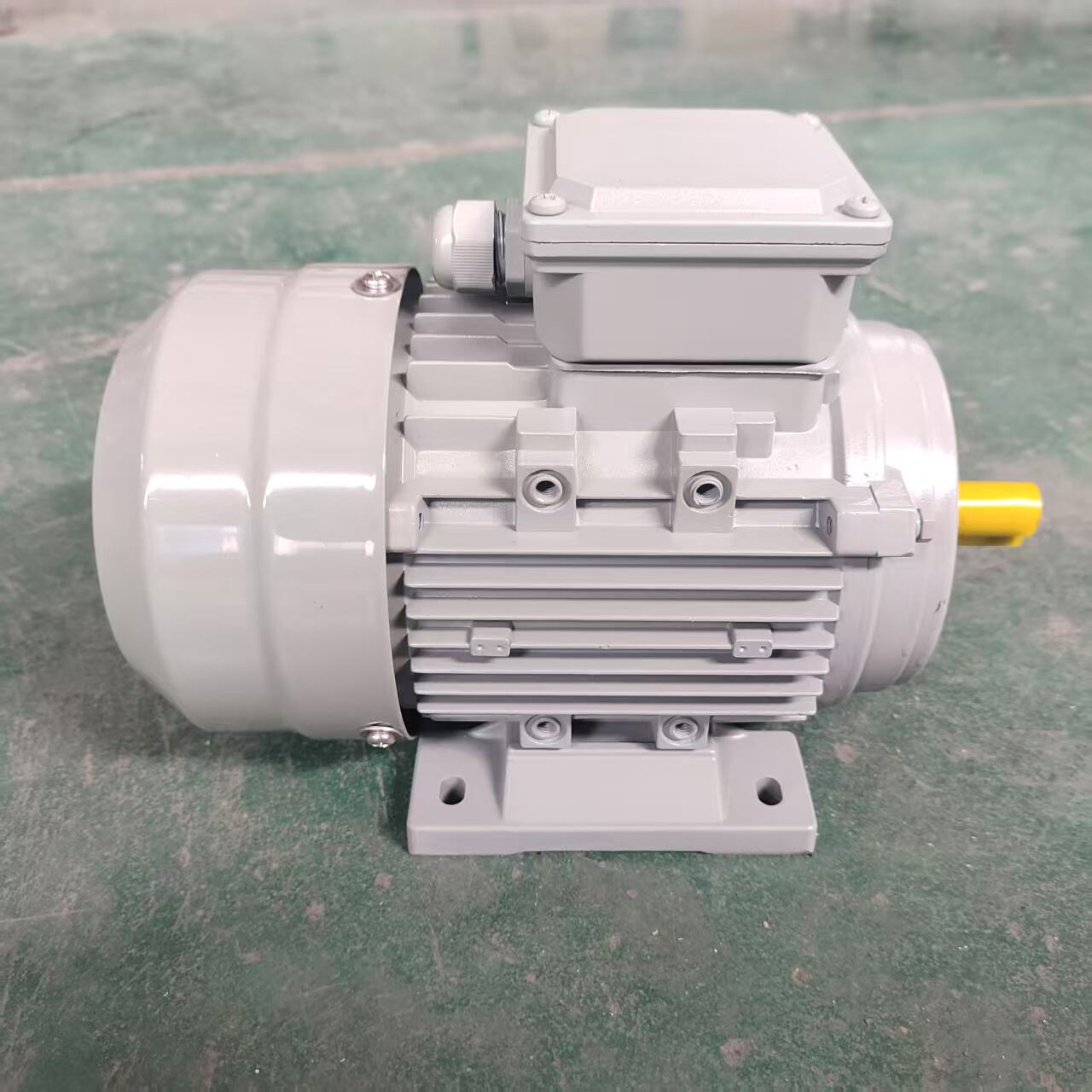

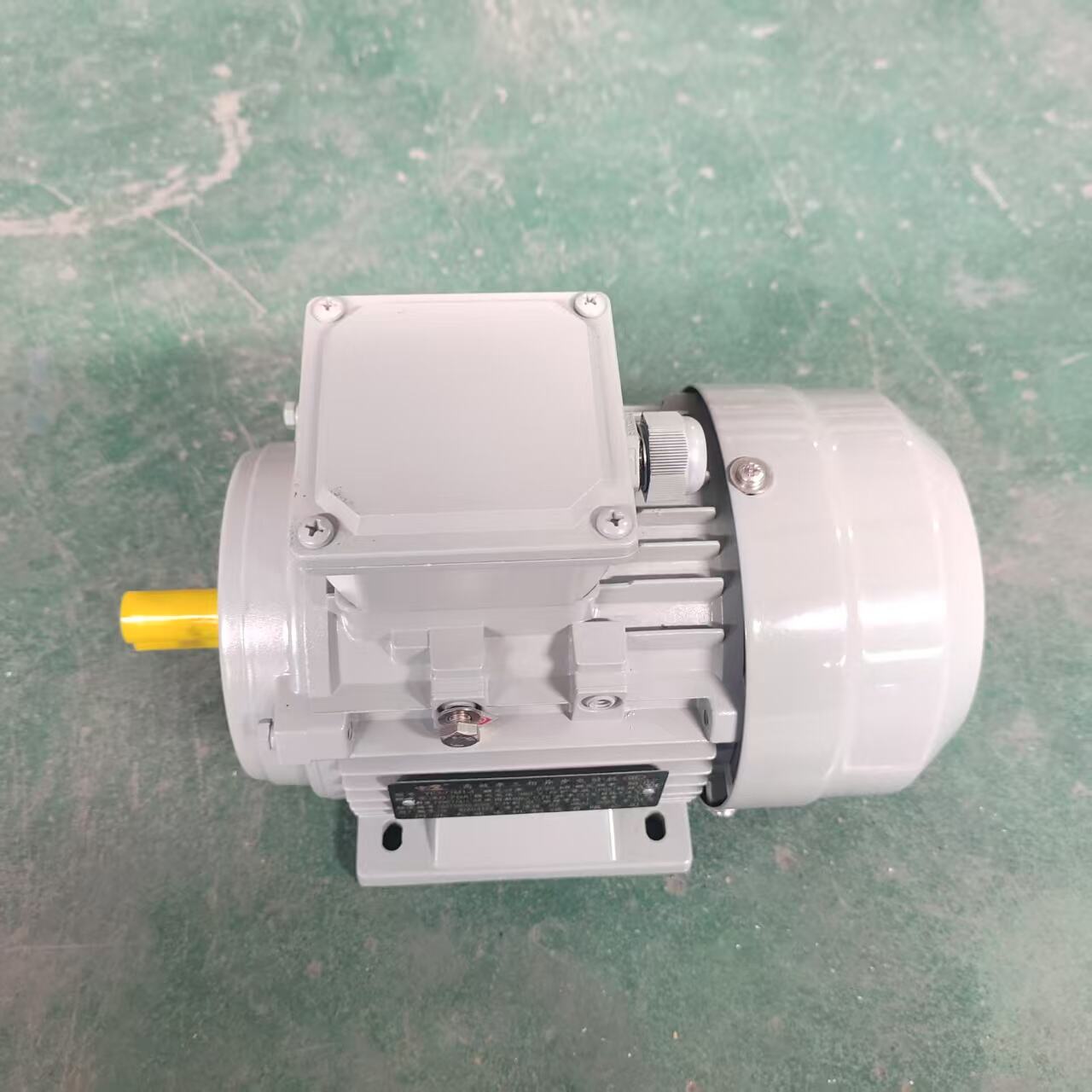

卸売用同期モーター

卸売用同期モーターは、交流電源の周波数に直接比例する一定速度で動作する高度な電気機械を表しています。この先進的なモータ技術は、ステータの回転磁界とロータとの間で正確な同期を維持し、さまざまな産業用途において優れた性能の一貫性を実現します。誘導モーターとは異なり、負荷の変動に関係なく卸売用同期モーターは完全な速度制御を達成できるため、正確なタイミングと連携が求められる用途に最適です。その基本的な動作原理は、ステータの交流電流とロータの直流励磁システムとの間の電磁的相互作用に基づいています。これにより、ロータの回転速度が電源周波数に固定される強力な磁気結合が生じ、比類ない運転安定性を提供します。現代の卸売用同期モーター設計では、効率の最大化とメンテナンス要件の最小化のために、先進的な材料と最先端の製造技術が採用されています。モーターの構造は通常、分布巻線を備えた堅牢なステータハウジングと、永久磁石または電磁石を搭載した特別設計のロータから構成されます。温度管理システムはさまざまな負荷条件下でも最適な性能を保証し、高度な制御システムにより正確な速度およびトルク制御が可能になります。これらのモーターは、高出力密度、優れた効率、信頼性の高い長期運転が求められる用途に特に適しています。卸売用同期モーターは、力率1(ユニティ)または進み力率で運転できる能力を持つため、電力系統の力率改善やエネルギー最適化において特に価値があります。産業施設では、このような先進モーターシステムを導入することで、電力コストの削減と電力品質の向上が実現できます。繊維製造、製紙、自動組立ラインなど、正確なタイミングを必要とする製造プロセスは、卸売用同期モーター技術の一貫した性能特性に大きく依存しています。