先進的な回転数

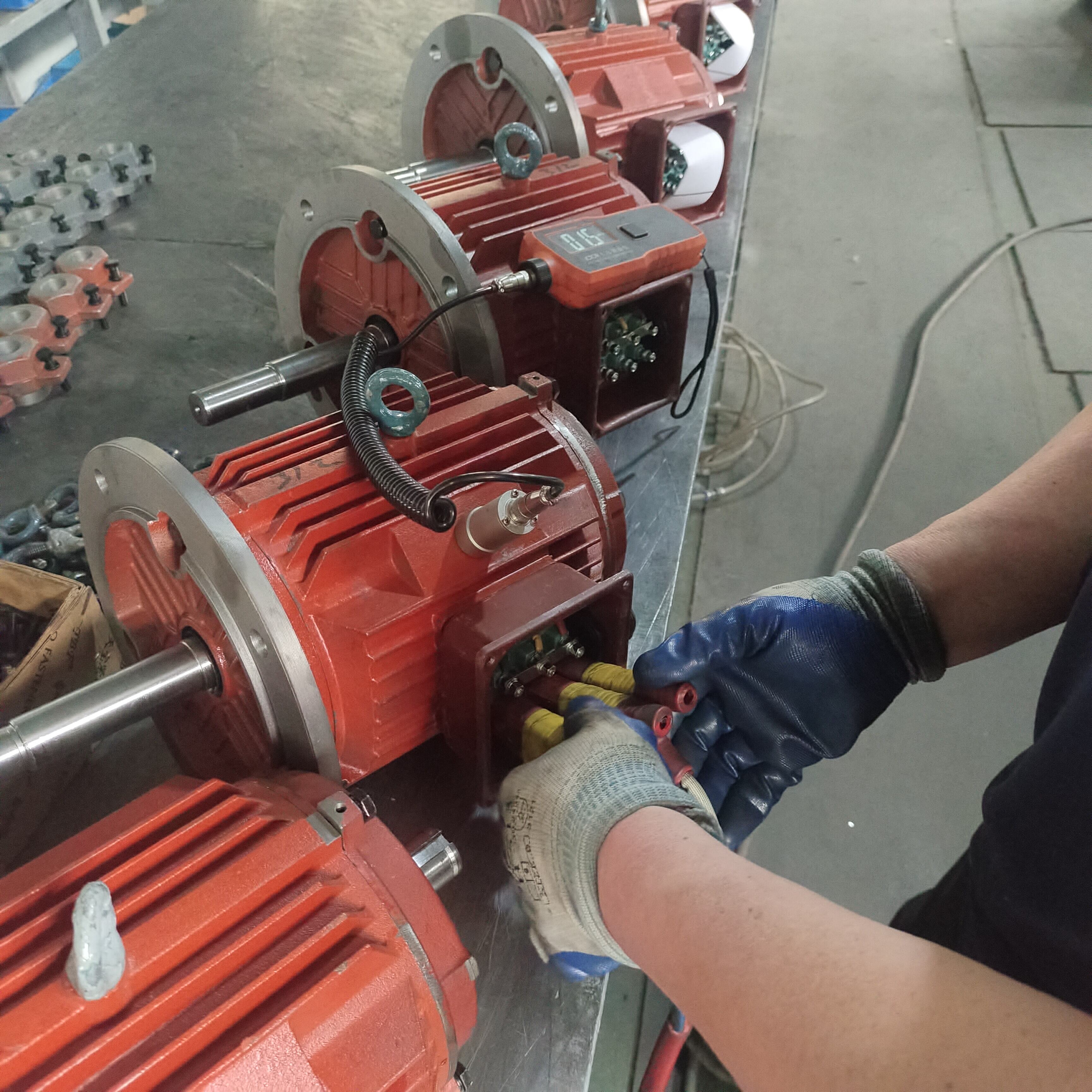

高精度回転速度技術は、複数の業界にわたり機械および設備の動作方法を変革する、最先端の技術的ブレークスルーを表しています。この高度なシステムは精密工学を活用し、最適な制御と安定性を維持しながら、かつてないレベルの回転速度を実現します。高精度回転速度技術の主な機能は、モーター性能の向上、スマートな速度制御、動的なトルク管理を通じて運用効率を最大化することにあります。これらのシステムには最先端のセンサーやリアルタイム監視機能が組み込まれており、さまざまな運用条件下でも最適な出力を保証するために、常に性能パラメータを調整します。高精度回転速度システムの技術的特徴には、可変周波数ドライブ、デジタル信号処理装置、適応型制御アルゴリズムが含まれ、これらはシームレスに連携して動作します。これらの構成要素により、システムは負荷の変動、環境の変化、運用上の要求に自動的に補正を行うことができます。高精度回転速度技術に内蔵された精密フィードバック機構は、性能要件に対して即座に応答し、一貫した出力品質と信頼性を確保します。高精度回転速度技術の応用範囲は、製造業、自動車、航空宇宙、再生可能エネルギー、産業オートメーションなど、多数の分野に及びます。製造現場では、これらのシステムが生産設備を極めて高い精度で駆動し、生産サイクルの高速化と同時にエネルギー消費の削減を可能にします。自動車業界では、電気自動車(EV)のモーターに高精度回転速度技術を活用し、優れた性能とバッテリー寿命の延長を実現しています。航空宇宙分野ではタービンエンジンや推進システムにこの技術を採用しており、信頼性と効率が極めて重要となる場面でその価値を発揮します。再生可能エネルギー分野では、風力タービンや水力発電機に高精度回転速度技術を導入し、発電効率の最大化を図っています。高精度回転速度技術の汎用性により、マイクロレベルの微調整を要する高精度用途から、堅牢な性能が求められる重工業用途まで幅広く対応可能です。この適応性により、組織は多様な運用環境にこれらのシステムを導入しつつ、一貫した成果と生産性指標の改善を達成できます。