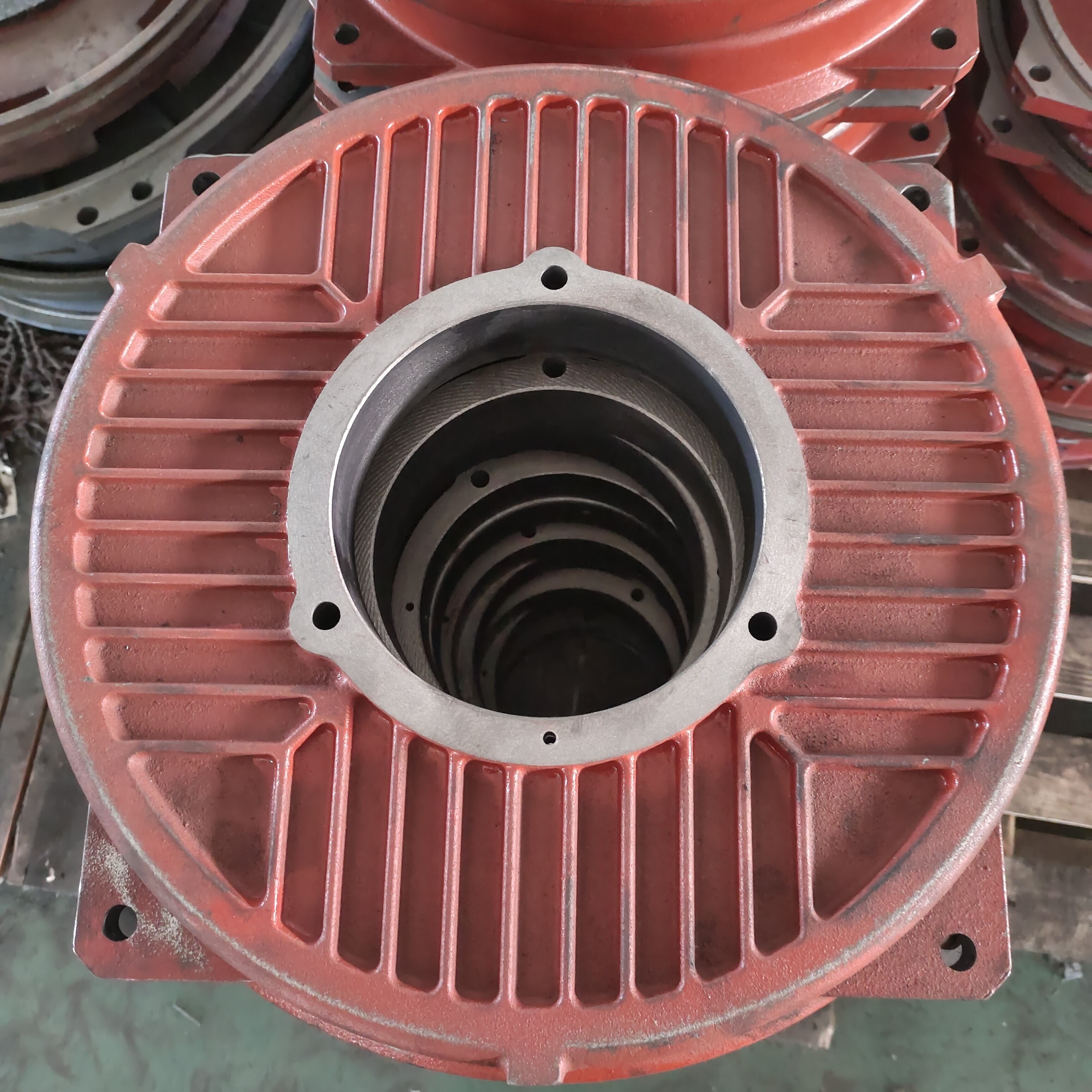

Ճշգրիտ արտադրություն՝ օպտիմալ կատարողականի համար

Արտադրության գերազանցությունը տարբերում է հայտնի վերջնական պլատը ճշգրտության մեքենայական գործընթացների եւ առաջադեմ արտադրական տեխնոլոգիաների միջոցով, որոնք ապահովում են չափերի ճշգրտությունը, մակերեւույթի որակը եւ արտադրանքի բոլոր միավորների կատարողականի համահունչությունը: Համակարգչային վերահսկողությամբ մեքենայական կենտրոնները, որոնք օգտագործվում են վերջնական պլատի արտադրության մեջ, պահպանում են տոլերանտությունները, որոնք չափվում են մեկ դյույմի հազարամյակների մեջ, ստեղծելով կատարյալ համատեղելի մակերեսներ, որոնք օպտիմալացնում են կնքման արդյունավետությունը Որակի ապահովման արձանագրությունները, որոնք կիրառվում են ամբողջ տարածված վերջնական պլատի արտադրության ընթացքում, ներառում են համապարփակ ստուգման ընթացակարգեր, նյութերի ստուգման փորձարկումներ եւ կատարողականի հավաստում, որոնք երաշխավորում են, որ յուրաքանչյուր բաղադրիչ համապատասխանում է խիստ արդյունաբերական ստ Բարձրորակ գործիքային համակարգեր, որոնք օգտագործվում են վերջնական պլատի արտադրության տարածված գործընթացներում, օգտագործում են ադամանդով ծածկված կտրող գործիքներ եւ ճշգրտության սարքավորումներ, որոնք պահպանում են մշակումների հետեւողական պարամետրերը, ապահովելով բարձր ծավալների արտադրության Ջերմաստիճանային վերահսկողությամբ արտադրական միջավայրերը պաշտպանում են հայտնի վերջնական պլաստիկին ջերմային փոփոխություններից, որոնք կարող են ազդել մշակումների ընթացքում չափերի կայունության վրա, պահպանելով վերջնական կիրառություններում օպտիմալ կնքման կատարման համար անհրաժեշտ կրիտիկական հանդուրժողականությունները: Բազմահյուսանի մեքենայական հնարավորությունները թույլ են տալիս ստեղծել բարդ երկրաչափություն հանրաճանաչ վերջնական պլատի նախագծում ՝ ներառելով բարդ հատկություններ եւ մակերեւույթի շրջանակներ, որոնք բարձրացնում են կնքման արդյունավետությունը ՝ պահպանելով կառուցվածքային ամրությունը եւ ամրությունը գործառնական լար Ավտոմատացված ստուգման համակարգերը ստուգում են յուրաքանչյուր հայտնի վերջնական պլատի չափերի ճշգրտությունը եւ մակերեսի որակը արտադրական գործընթացների ընթացքում, հայտնաբերելով եւ ուղղելով ցանկացած շեղում, նախքան բաղադրիչները հասնում են վերջնական փաթեթավորման եւ հաճախորդներին առաքման: Հետեւելիության համակարգերը, որոնք կիրառվում են վերջնական պլանշետների արտադրության մեջ, պահպանում են նյութերի աղբյուրների, արտադրության պարամետրերի եւ որակի փորձարկումների արդյունքների մանրամասն արձանագրություններ, ինչը հնարավորություն է տալիս ապահովել որակի ամբողջական վերահսկողություն եւ արագ արձագանք հաճախորդների հարցումների կամ եր Բարձրակարգ արտադրության ոլորտում շարունակական բարելավման նախաձեռնությունները ներառում են հաճախորդների հետադարձ կապը, արտադրանքի կատարման տվյալները եւ առաջացող տեխնոլոգիական զարգացումները, որպեսզի ժամանակի ընթացքում բարելավվեն արտադրական գործընթացները եւ արտադրանքի կատարման հատկանիշները: