اختيار وتركيب محركات التردد المتغير

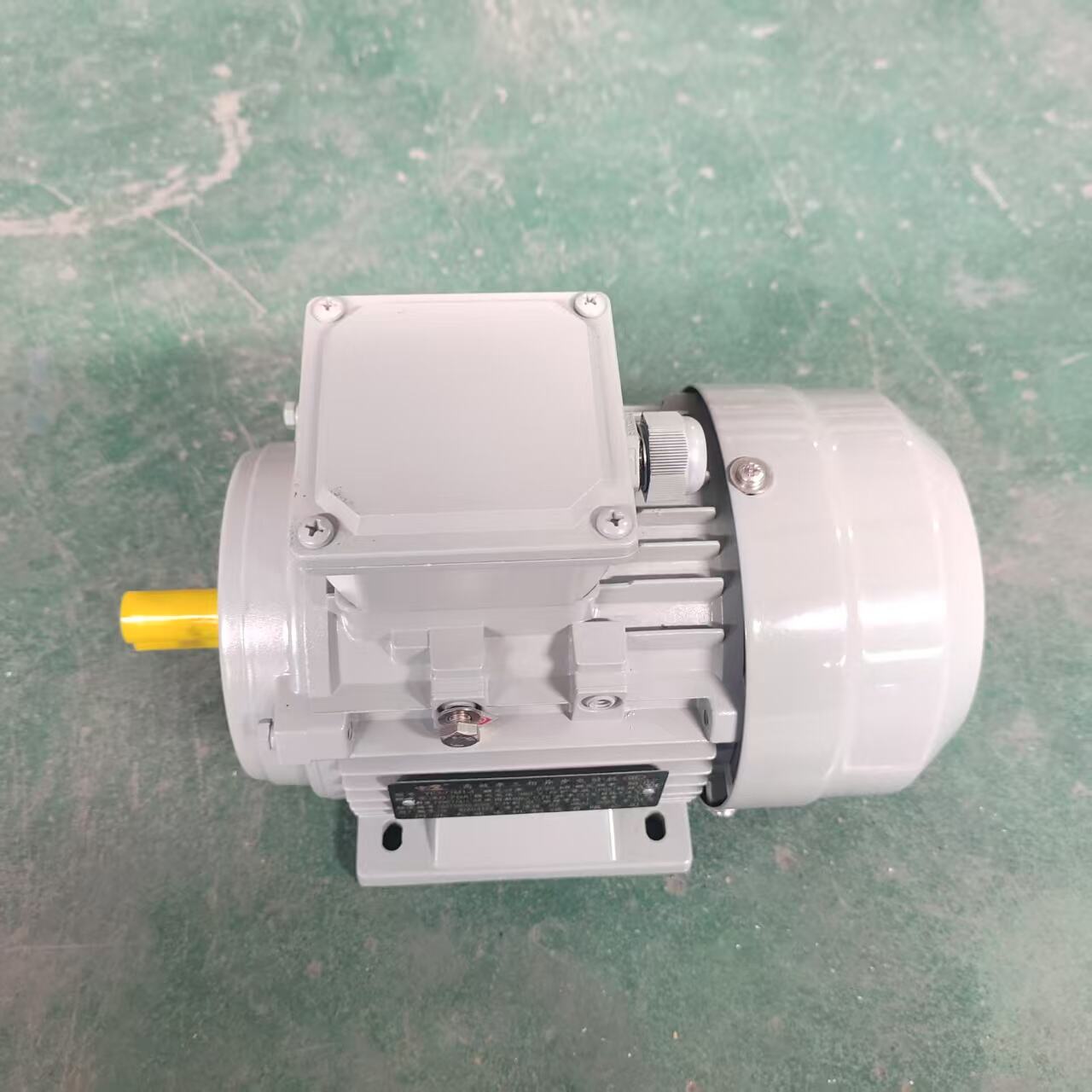

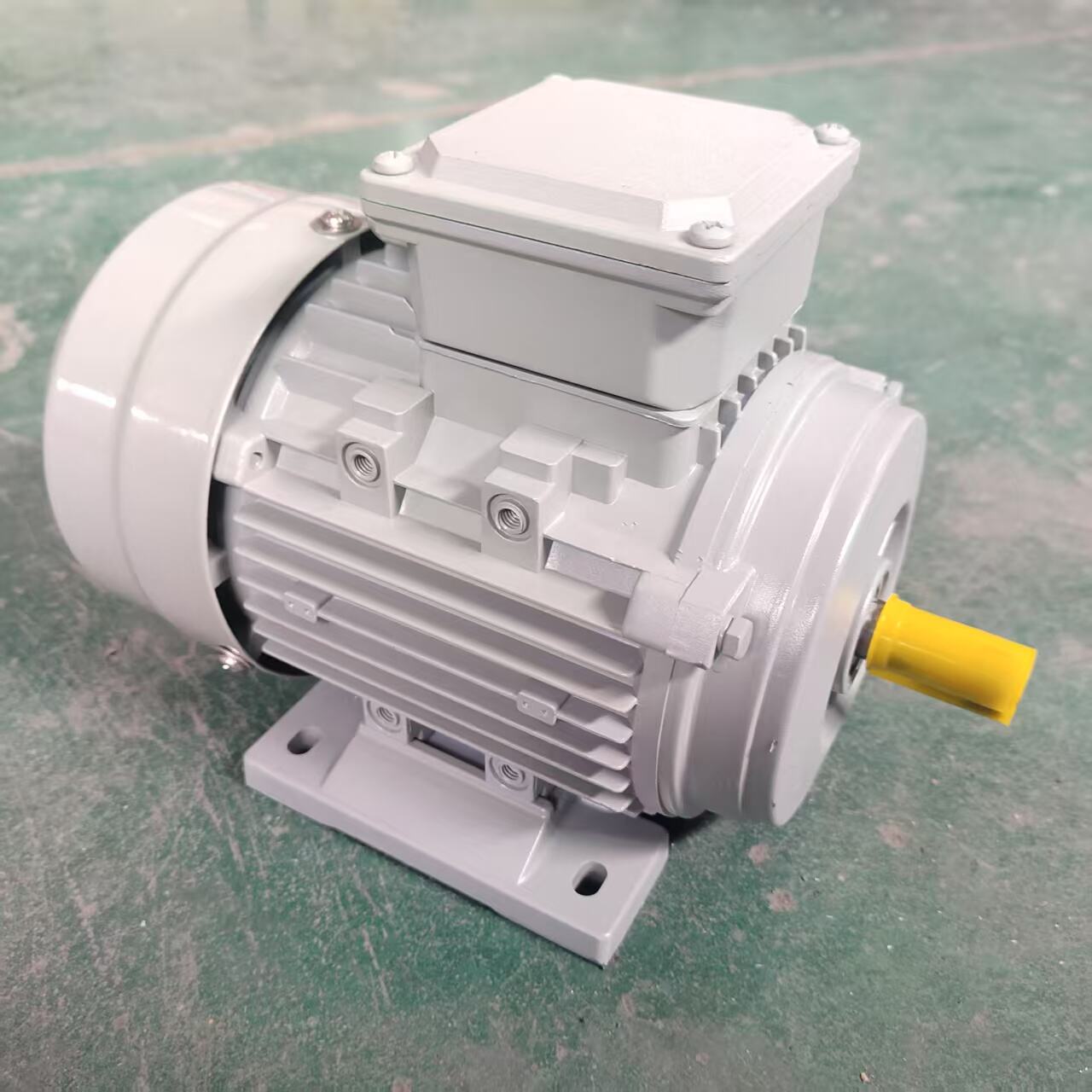

اختيار وتركيب محركات التردد المتغير مقدمة عن محركات التردد المتغير تقع المحركات الكهربائية في قلب العمليات الصناعية، حيث تشغّل المضخات والضواغط والناقلات وأنظمة التهوية. تقليديًا، تعمل هذه المحركات...

عرض المزيد